MEASURED RUNNING PARAMETERS

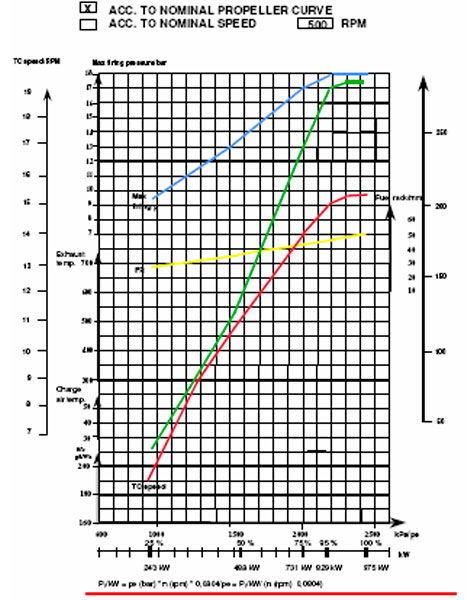

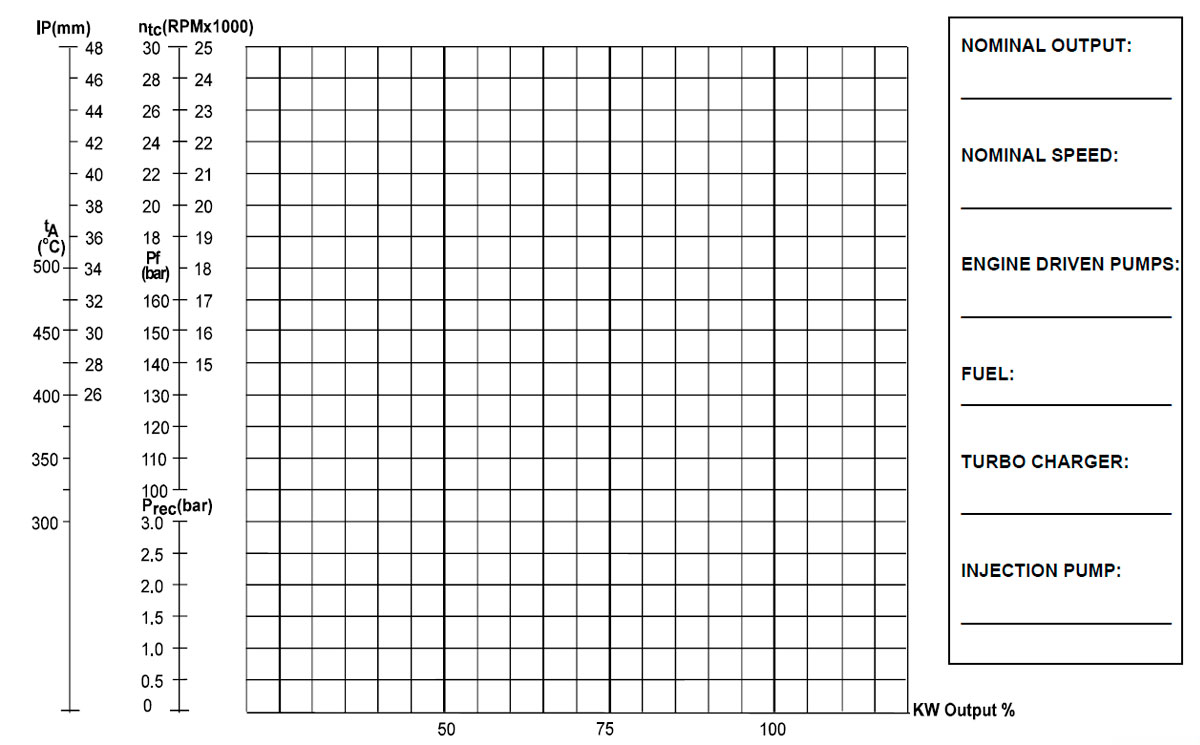

- Engine speed

- TC speed

- Fuel rack position

- Charge air pressure / temperature

- Pressure difference over CA cooler

- Pressure difference over cylinders

- Exhaust gas temperatures

ENGINE SPEED:

- Measured by cam shaft wheel, or flywheel.

- Unstably engine speed can be caused by wrong governor settings, worn/jamming regulating mechanism.

- Engine speed controls pre.lub pump start and stop, pre.heating start and stop, by-pass valve function.

- Alarm / safety blockings.

- Safety functions; clutch opening, over speed.

TURBO CHARGER SPEED:

- An important factor to follow since the turbo speed gives an indication when the nozzle ring gets dirty. I.e. the turbo speed increases slightly.

FUEL RACK POSITION

- Indicates amount of sprayed fuel oil (engine load).

- Increased fuel rack index (same load) can be result of worn pump (bigger internal leakages) or change on fuel quality, lower heat value.

IGNITION QUALITY PARAMETERS:

- Energy

- Viscosity

- Maximum firing pressure.

- Injection delay

- Ignition delay

ENERGY COMPARISON

- The injection pump is a volumetric pump

- The higher the density the more energy it contains per volume unit

- The density difference between HFO and MDO is larger than the difference in net calorific value

VISCOSITY COMPARISON

- The viscosity of MDO is lower than the viscosity of HFO (even HFO is heated)

- Lower viscosity fuels result in more internal leakage in the injection pump from the high pressure side to low pressure side.

- Internal leakage has to be compensated by giving more fuel rack

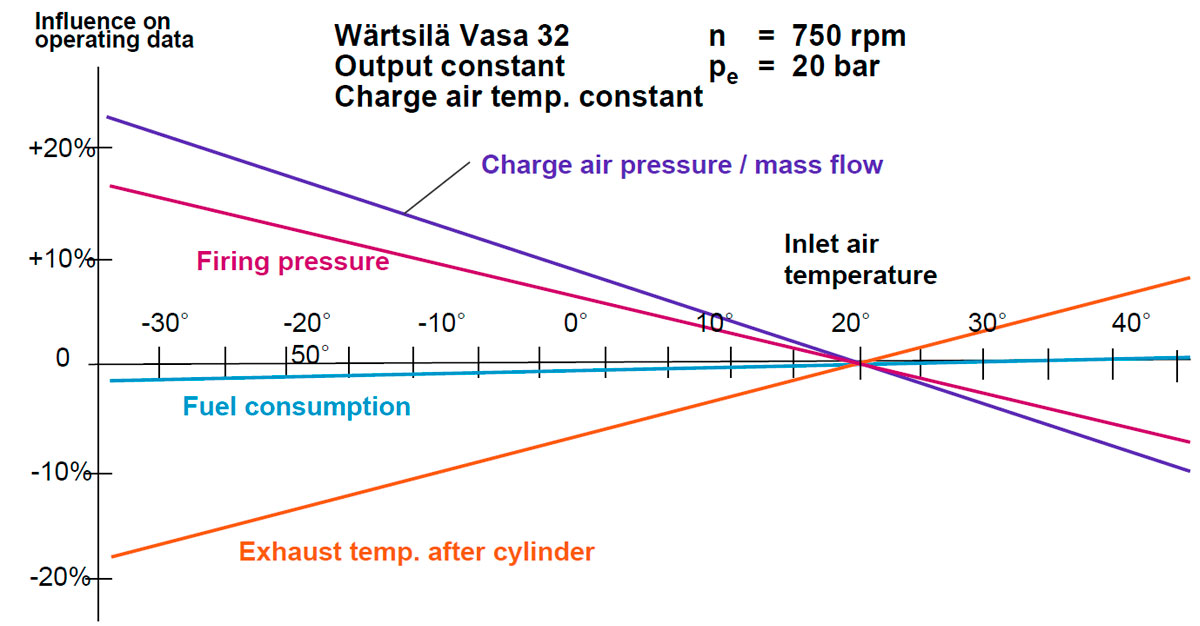

MAXIMUM FIRING PRESSURE

- Dependent on the charge air pressure

- To achieve proper combustion, the firing pressure has to be high and thus also the charge air pressure

- Timing of the fuel pump

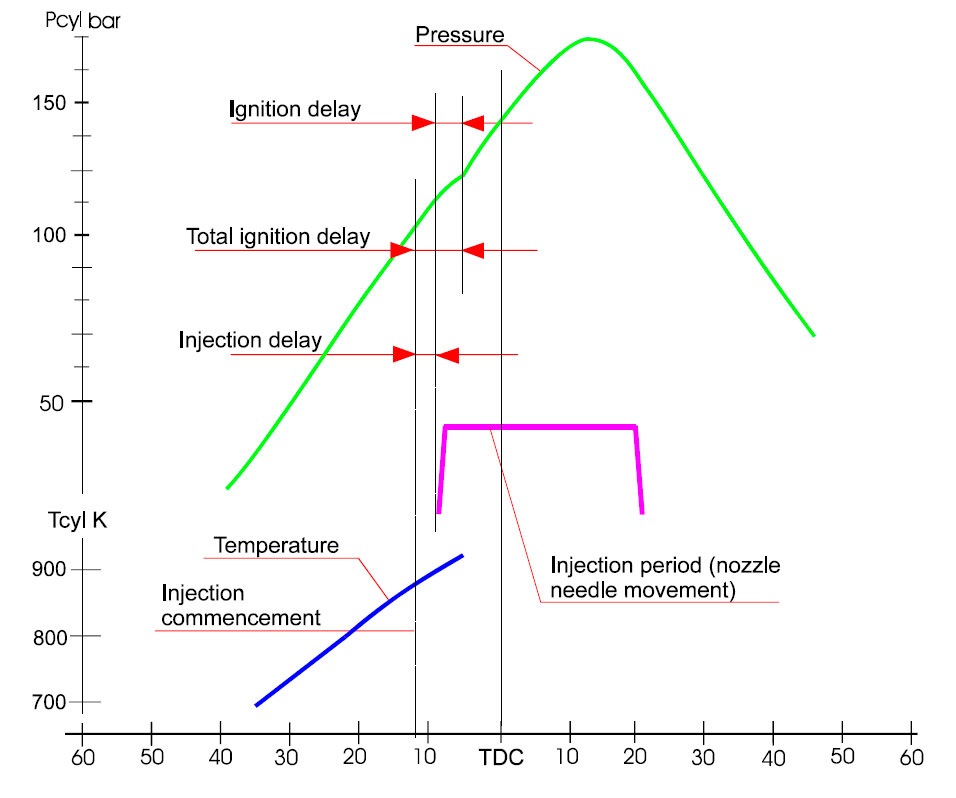

- INJECTION DELAY is the time it takes to build up a pressure higher than the opening pressure of the nozzle.

- Normally 4...5 ° of crank angle

- The delay is comparable to the condition of injection equipment

- IGNITION DELAY is the time gap between the commencement of injection and the commencement of ignition.

- Dependent on the fuel quality

- Compression temperature has a big influence on the ignition delay

- Compression temperature is not high enough for the fuel to ignite longer ignition delay

HIGHER PEAK PRESSURES AND HIGHER EXHAUST GAS TEMPERATURES.

- Normally 1...2 ° of crank angle.

- Too early timing of injection

- Higher peak pressure

EXHAUST GAS TEMPERATURE AFTER CYLINDER

- Measured individually after each cylinder

- Each cylinder has two measuring points.

- The average temperature of all exhaust temperature sensors is approximately 100 °C lower than the exhaust gas temperature before the turbine.

- Maximum allowed difference between valves in one cylinder.

- Maximum allowed difference of one cylinders average from the average of the all cylinders , alarm.

- In normal operation the average temperature Cylinder temperature deviation can be up to 30 - 40 °C.

- Engine is (depending of installation) provided with a safety slow down arrangement if the temperature difference is too big

- A 10 °C increase in ambient temperature will result approximately 15 °C increase in exhaust gas temperature

EXHAUST GAS TEMPERATURE AFTER TURBOCHARGER

- Indicates the kinetic energy of the exhaust gases that are running the turbine

- Indicates the condition of the turbo, i.e. scavenging of the engine

- If a de-Nox catalysator is installed the temperature has to exceed certain level to ensure the function of the catalysator

PRESSURE DIFFERENCE OVER THE CYLINDERS:

- Measuring the pressure difference between charge air manifold and exhaust gas manifold. gives an indication of how well the scavenging works.

- Depends on the turbocharger, therefore values below should be considered as allusive

- The bigger the Dp is the better scavenging.

- Is normal value with 100% load varies depending of installation once the value has been dropped down, it is an indication that something is wrong with the engine -e.g. dirty nozzle ring & turbine

DIRTY CHARGE AIR COOLER:

- Indicated by the increase of the pressure difference over the cooler, remember that the cleaning of the cooler is aggravated with the dirtiness of the cooler.

CONSEQUENCES:

- Less fresh air to cylinders

- Higher exhaust gas temperatures

- Improper combustion

- Low peak pressures

- More deposits to nozzle ring

- Increased SFOC

- Increased SLOC

- Higher fuel rack reading at the same load

CONDENSE WATER IN CHARGE AIR:

- Condense water that is condensing in the cooler has to be drained out

- Causes wear in the pistons, piston rings and cylinder heads

- Will cause inlet seat ring problems

- The amount of condensed water may be reduced by increasing the charge

- Air temperature, but the maximum temp must not be exceeded which is 55 ° C

- Increases thermal loading of the engine

DIRTY NOZZLE RING:

- Indicated by;

- Slightly higher turbine speed

- Higher receiver temperature

- Decreased pressure difference over the cylinders

2. POSSIBLE CONSEQUENCES;

- Remainder pressure in the cylinders increase

- less fresh air to cylinders

- worse scavenging

- delayed combustion

- more deposit accumulations

- higher exhaust gas temperatures

- increased thermal load

- increased risk of engine failure

- piston seizure

- hot corrosion

- increased fuel consumption.

LOW PEAK PRESSURES-HIGH EXHAUST GAS TEMPERATURES:

- Obvious reason:

- DELAYED COMBUSTION

- Dirty air cooler

- dirty nozzle ring(s)

- injection nozzles in bad condition

- worn injection pumps

- a long injection delay

- bad fuel

- high CCAI value poor ignition properties

- high water content

- high exhaust gas temp

HIGH EXHAUST GAS TEMPERATURES:

- Obvious reason

- Injection valves in bad condition

- dirty nozzle ring

- dirty air cooler

- Low fuel viscosity

- worn injection pumps

- bad fuel

- burned valves or seats

HIGH FUEL RACK READING COMPARED TO LOAD

- Worn injection pumps

- more internal leakage

- too low viscosity of the fuel

- more internal leakage

- low heat value of the fuel

- high water content

- dirty fuel filter

- too low fuel pressure

- big fuel leakage

Литература

www.wartsila.com