Content

- Automation system arrangement

- Local control panel

- Local display unit

- Main cabinet

- MCM-700 Main control module

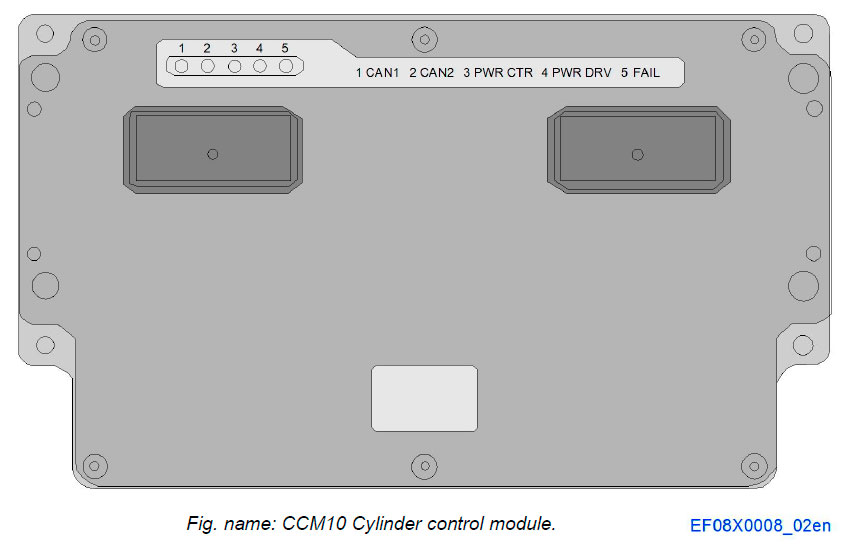

- CCM-10 Cylinder control module

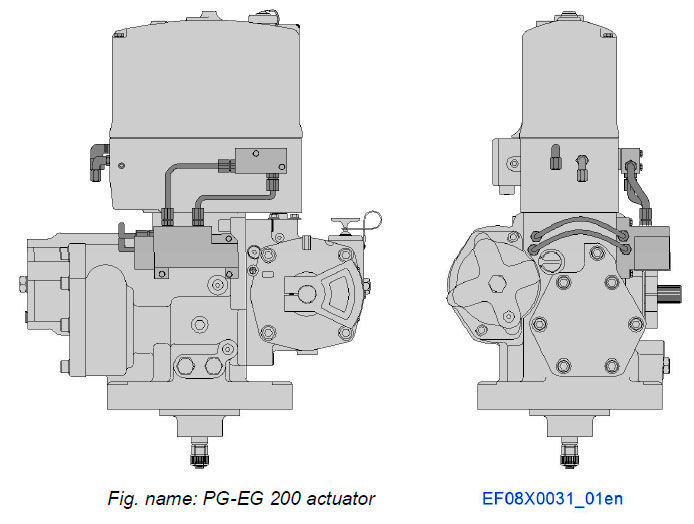

- Actuator

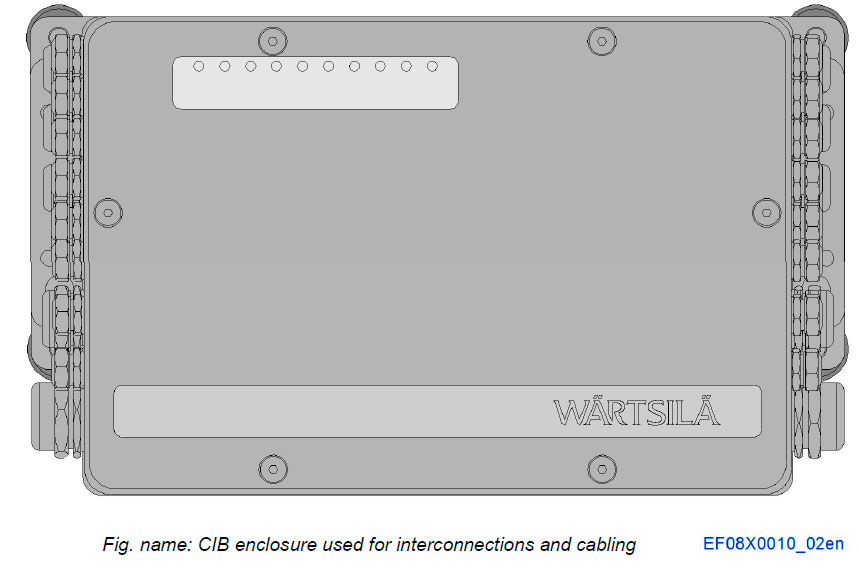

- Cabling and CIB (Cabling Interface Box)

- WECS 8000

- RM-11 Relay module

- Power distribution and filtration

- Other parts of WECS 8000

- Engine speed measurement

- Engine modes

- Engine control processes during operation

WECS 8000

General

THE CONCEPT

The DF engine concept by itself is based on fuel redundancy. In addition, WECS 8000 is totally distributed, in order to split up functionality and make boundaries between the categories control and monitoring, but also to build natural redundancy into the system. This means that redundancy control strategies are utilised, in the event of a main sensor/component failure.

THE DESIGN

WECS 8000 is an engine built, distributed control- and monitoring system specifically developed by Wärtsilä to meet the performance requirements set out for engines using genuine Dual Fuel technology.

It handles all strategic functionality related to operation both on gas and diesel fuel (such as electronically controlled gas admission and pilot fuel injection, diesel actuator control, engine safety and fuel switch-over logic).

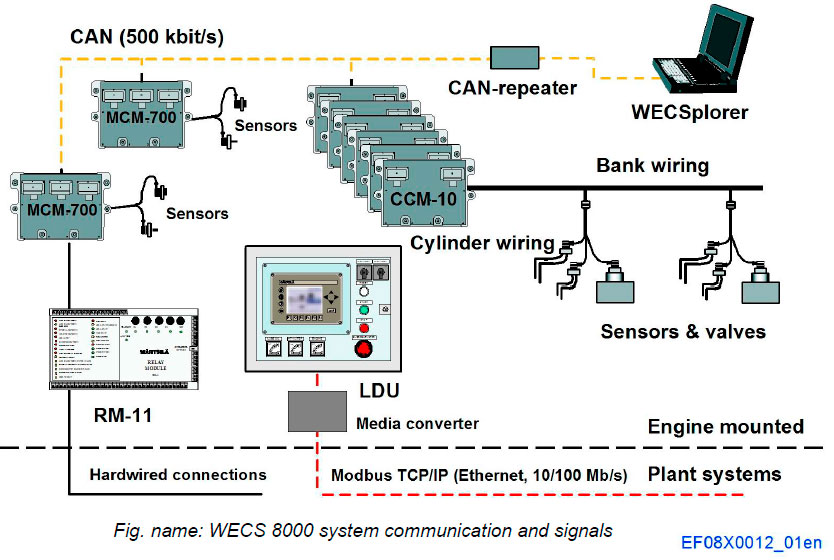

THE COMMUNICATION

All the modules communicate with each other via an inter-module communication bus based on the CAN protocol. CAN is a communication bus specifically developed for compact local networks, where high speed data transfer and safety are of very high importance.

Some safety critical back-up features such as overspeed protection is handled by the relay module (discrete cabling).

Automation system arrangement

The WECS 8000 system is a fully integrated engine management system, designed for harsh environments. The engine-built system handles all necessary monitoring- and strategic control features needed on a DF engine. The system architecture is based on distributed electronic modules, thus the measurements and controls are occurring where locally needed on the engine. The functionality of WECS 8000 comprises the following main categories:

- Handling of engine slow turning, start & stop sequences

- Changing of fuel modes

- Instrumentation & communication

- Speed measurement

- Engine safety

- Speed/load control

- Gas pressure- & gas admission control

- Pilot pressure- & pilot injection control

- Air/fuel ratio control

- Cylinder balancing & knock control

- Diagnostics

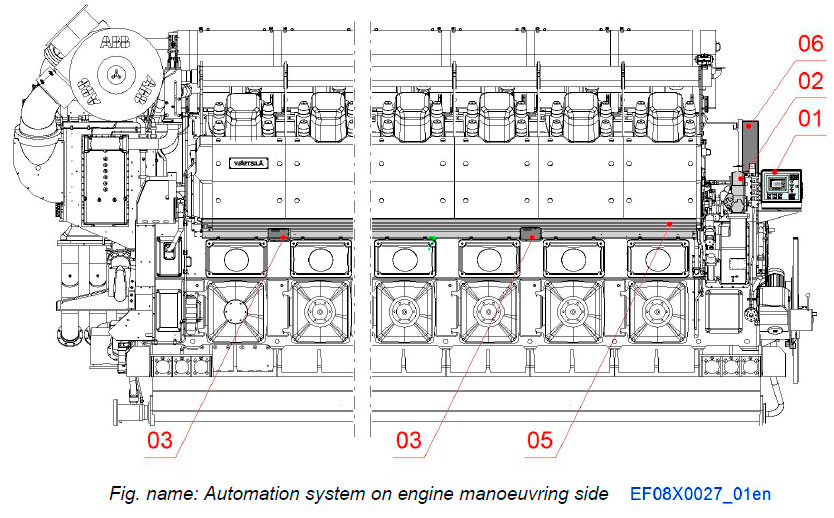

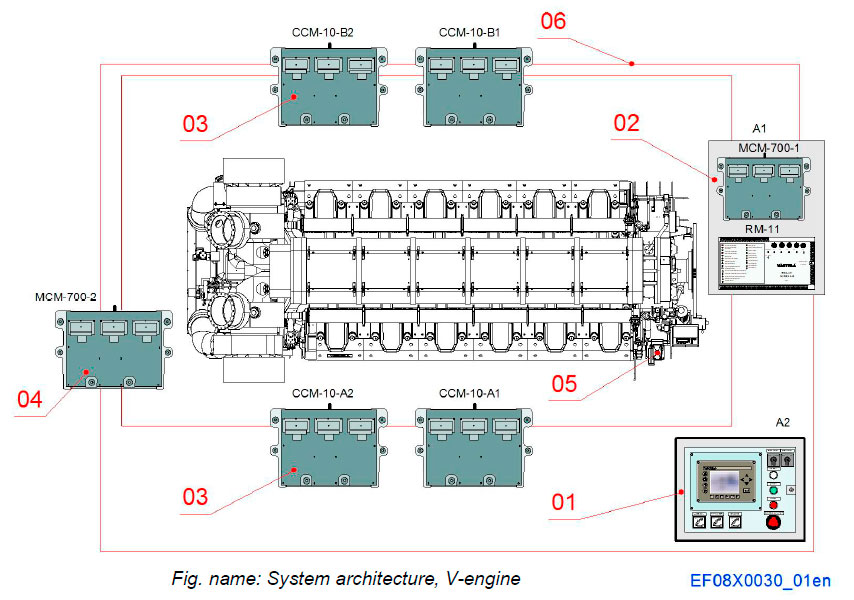

SYSTEM COMPONENTS

- 01 Local control panel

- 02 Actuator

- 03 CCM-10, Cylinder control module (1-n)

- 05 Cable rail

- 06 Main cabinet

Automation system arrangement

The system consists of a number of distributed electronic modules, all interconnected with a multibus. The exact structure of the system depends on the engine’s cylinder configuration. The electronic modules communicate with each other over a communication bus, and this communication is based on the CAN (Controller Area Network) protocol.

Some safety critical back-up control functions are handled over hardwired point-to-point wiring, and with a separate back-up module.

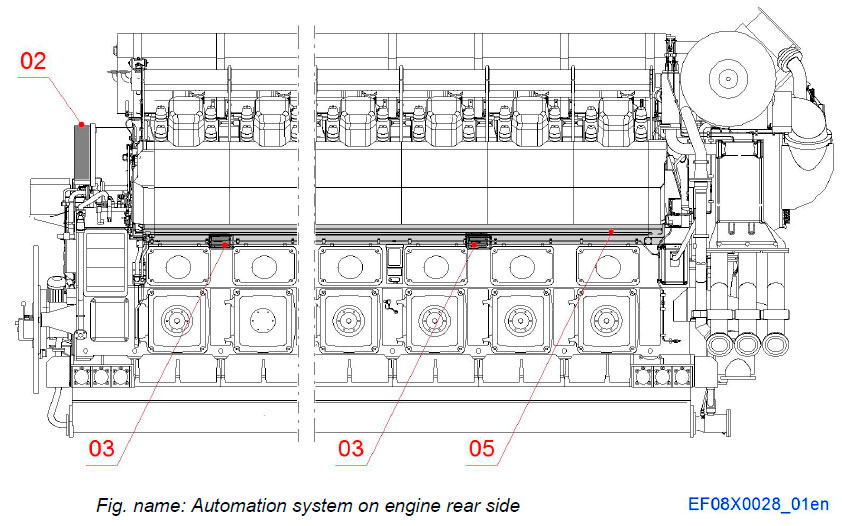

SYSTEM COMPONENTS

- 02 Power module

- 03 CCM-10, Cylinder control module (1-n)

- 05 Cable rail

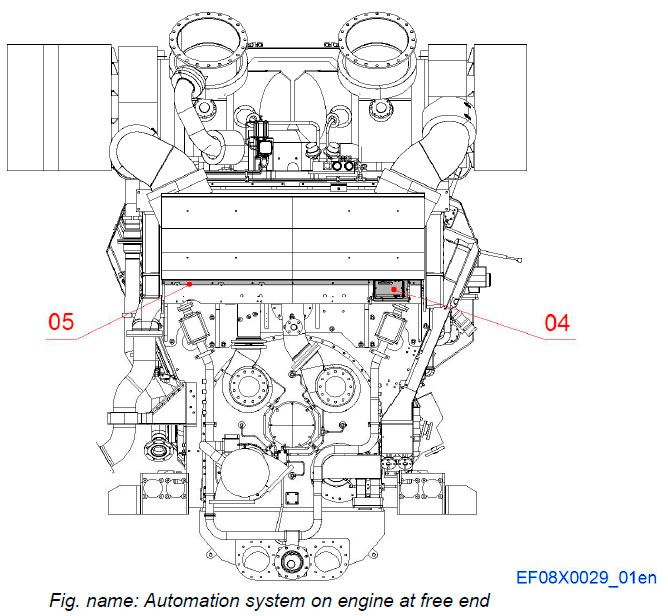

Automation system arrangement

SYSTEM COMPONENTS

- 04 MCM-700-2, Main control module

- 05 Cable rail

Automation system arrangement

01 LOCAL CONTROL PANEL

- Graphical display

- Control buttons

- Emergency stop

- Back-up instruments

02 MAIN CABINET

- Main control module

- Power module

- Relay module

- Diesel actuator converter

- CAN repeater

- Modbus port

03 CYLINDER CONTROL MODULES

- Main gas admission

- Pilot fuel injection

- Cylinder measurements

04 MAIN CONTROL MODULES

- Data acquisition

05 ACTUATOR

06 CAN COMMUNICATION BUS

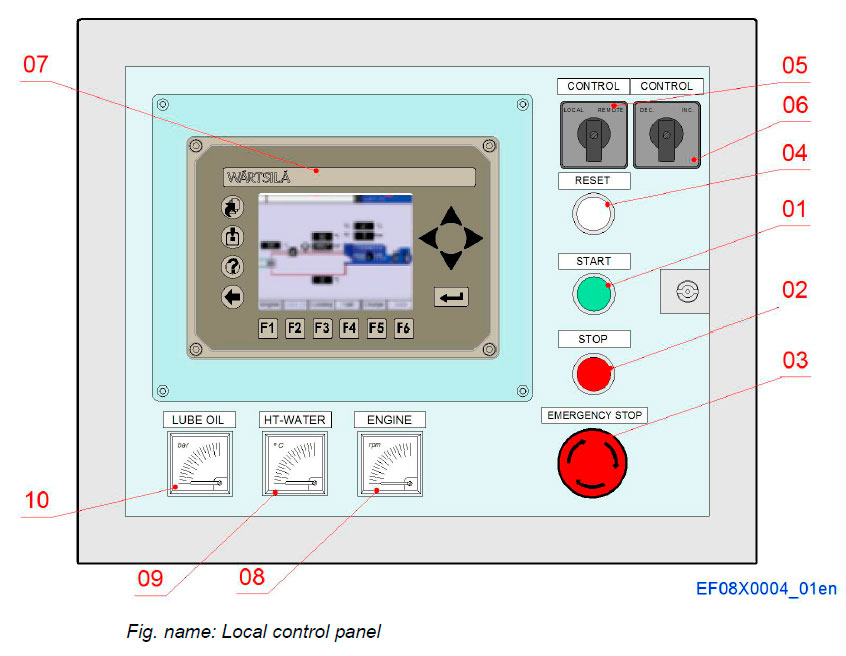

Local control panel

There is a local control panel on the engine, where most engine measurements and statuses can be monitored, and where the local push buttons and selector switches are located. For viewing of the engine parameters, there is an electronic LDU (Local Display Unit) used, with a number of menus and menu selection buttons. Mechanical back-up instruments for engine speed, HT water temperature and lubricating oil pressure are also arranged. The local push buttons and switches are the following:

SYSTEM COMPONENTS

- 01 START button

- 02 STOP button

- 03 Emergency STOP

- 04 Shut down RESET button

- 05 Remote/Local mode switch

- 06 Speed increase/decrease switch

- 07 Local display unit

- 08 Engine speed indicator

- 09 HT cooling water temperature indicator

- 10 Lubricating oil pressure indicator

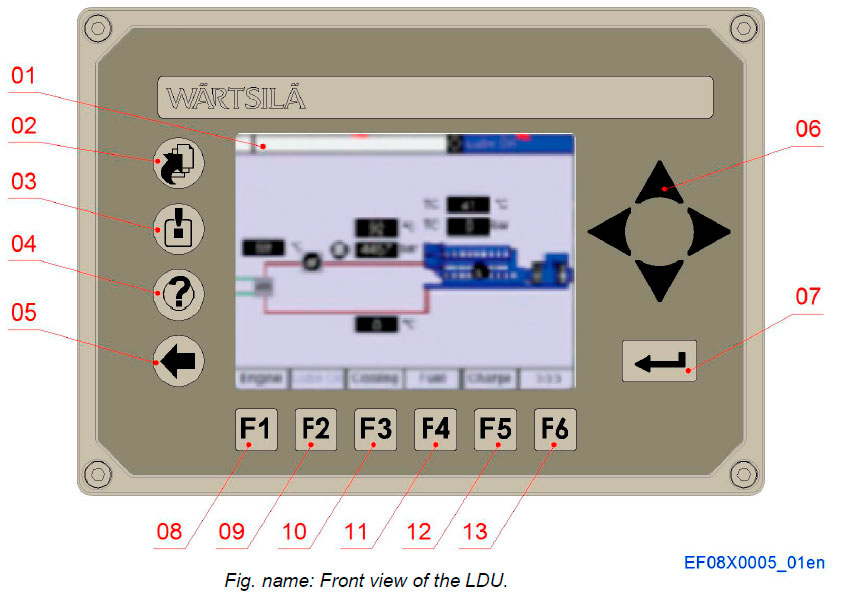

Local display unit

The LDU replaces the traditional pressure gauge panel, thermometers and other engine instruments. The LDU is connected to the main control module over the CAN bus, over which it receives all data to be displayed. The graphic display has a number of different pages (menus), and integrated key buttons for activation of these pages.

SYSTEM COMPONENTS

- 01 Graphic display

- 02 Main page

- 03 Alarm log

- 04 Help page

- 05 Back command

- 06 Navigation

- 07 Enter command

- 08 Engine temperatures

- 09 Lube oil system

- 10 Fuel system

- 11 Cooling water system

- 12 Charge air system

- 13 F6 + F1 Miscellaneous measurements F6 + F2 Knock measurement

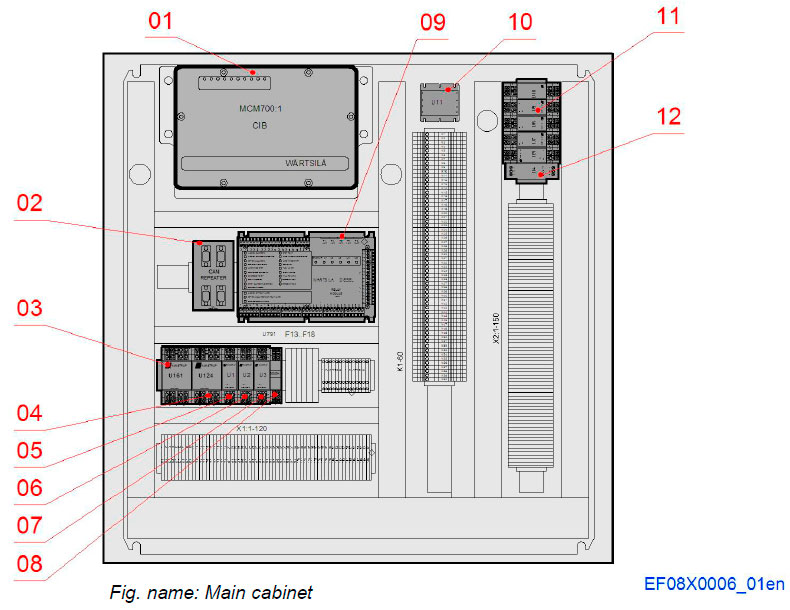

Main cabinet

SYSTEM COMPONENTS

- 01 MCM-700 Main control module

- 02 Electronic unit, CAN-repeater

- 03 Converter

- 04 Converter

- 05 Converter

- 06 Converter

- 07 Converter

- 08 Hour counter

- 09 RM-11 Relay module

- 10 DC/DC converter

- 11 Converter

- 12 Signal isolator/converter

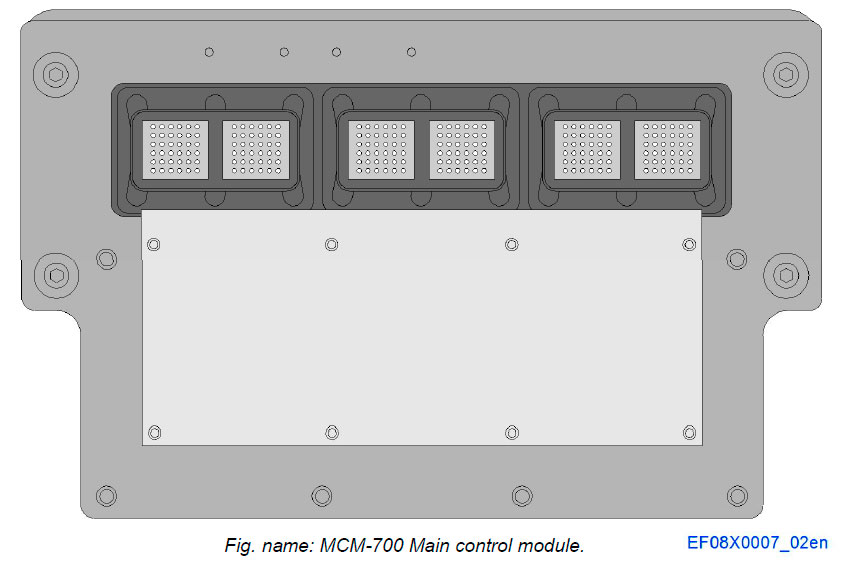

MCM-700 Main control module

This module is the master in the WECS 8000 system. It handles the processing of all strategic engine control functions. The main processes are the engine start- & stop sequences, engine safety, and the combustion control.

Calculations are made based on the internal speed/load control algorithms, gas pressure, gas admission and pilot fuel injection/timing. It handles the information sent by all other modules, and it sends reference signals to the cylinder control modules about gas admission, pilot fuel quantity and timing etc. It also communicates with systems external to the engine itself. A second MCM-700 module is also part of the system (at free end), exclusively for collecting of sensor signals and for control of the waste gate.

CCM-10 Cylinder control module

The cylinder control modules control the gas admission- and pilot fuel injection valves by means of using high-energy type PWM (Pulse Width Modulation) outputs. Each module is providing PWM-type control signals to three gas admission valves and three pilot fuel injection valves. The modules calculate the relevant injection duration and injection timing based on references sent over CAN from the main control module. In order to provide injection command signals at the relevant angular position, the cylinder control modules need accurate information from the engine’s speed and phase sensors.

Therefore the speed and phase signals are hard-wired to each cylinder control module. The cylinder control modules also handle cylinder specific measurements, i.e. exhaust gas temperature and cylinder knock measurements. All cylinder specific information as measured by these modules is sent over CAN to the main control module.

Actuator

This hydraulic-mechanical actuator is used in diesel- and back-up operating mode, for control of the fuel rack of the engine. The actuator receives a control signal from WECS 8000 main control module (via a current converter), and sets the fuel rack position accordingly.

Cabling and CIB (Cabling Interface Box)

Interconnections and cabling on the engine is utilizing a so called cabling interface box, CIB, which is acting as an interface between the control modules and their peripheral devices.

The CIB is a robust construction mounted on top of the control modules, it’s equipped with cable glands for the out-going cables and with multi-pin connectors for mating to the control module. Internally there is a printed circuit board containing spring loaded terminal strips, test connections, terminal resistors etc.

Screened, special cables for the demanding engine environment are used for all equipment. Control modules are interconnected with a special multi-bus cable, including power supply (24V), engine speed, engine phase, safety wire loop and CAN-bus, all doubled for redundancy reasons.

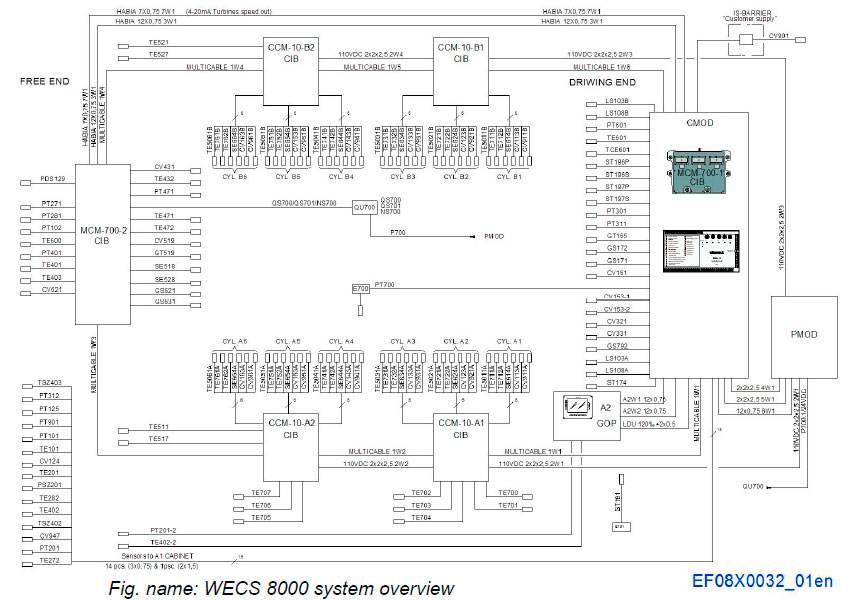

WECS 8000 SYSTEM OVERVIEW

An overview of the entire cabling of the DF engine, including references to each sensor.

WECS 8000

INTERNAL AND EXTERNAL COMMUNICATION ON DF ENGINES

WECS 8000 is a distributed system, where all the electronic modules communicate over the CAN-bus with each other. The system collects signals from various sensors at different locations on the engine, connected to locally mounted modules. The signals received are processed and compared with the control parameters given for all the active engine processes.

- These engine-strategic controls are processed in one of the two main control modules, which is the master of the system. This main control module also automatically controls the start- and stop sequences of the engine, as well as monitors the engine safety.

- The second main control module is exclusively used for collecting of sensor signals and for control of the waste gate.

- Several cylinder control modules are used, each module handles 3 cylinders. All the modules are mounted along the engine side close to the engine sensors or the control units they are reading or controlling. The data transferred over CAN between the modules, has a number of different rate groups for optimised and secured data transfer.

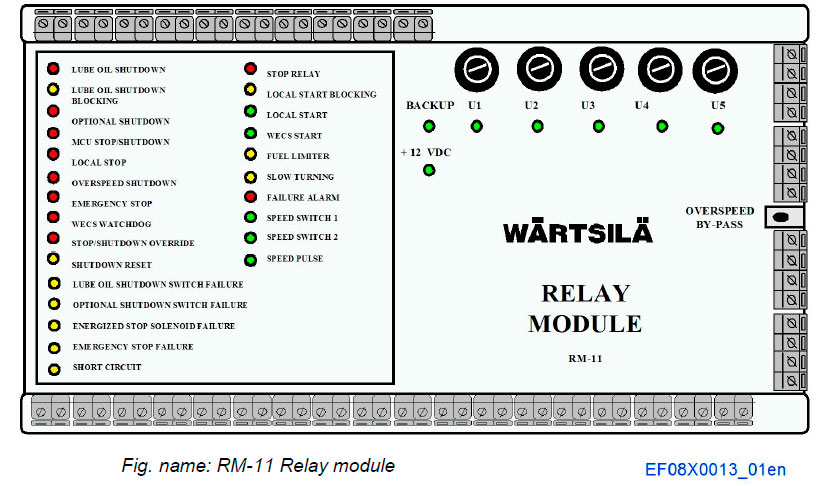

RM-11 Relay module

Unlike other parts of WECS, the RM-11 relay module electronics is based on analogue circuit technology (no microprocessor). The relay module, which is located in main cabinet A1, handles a number of back-up safety related functions on the engine. It also constitutes the hardwired interface between the main control module and the startslowturning-& stop solenoids of the engines, and partly also to the external systems.

Critical parameters such as engine speed, lubricating oil pressure and HT water temperature are monitored in this module, and in case of abnormal levels, a shutdown is initiated and controlled from this module, independently of the main control module. The relay module is located in the main cabinet of the engine and LED’s on it indicate the status of each input/output of it. Also all supply voltages have their own LED.

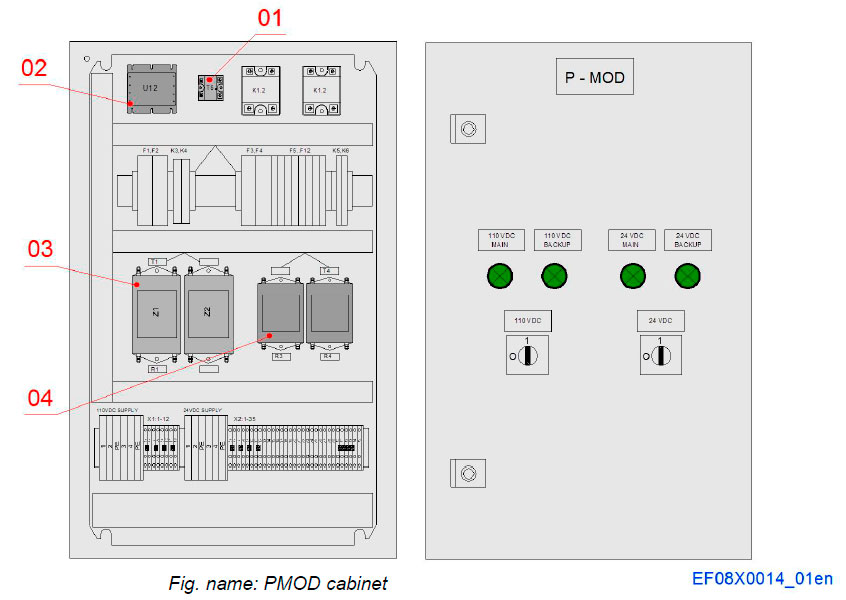

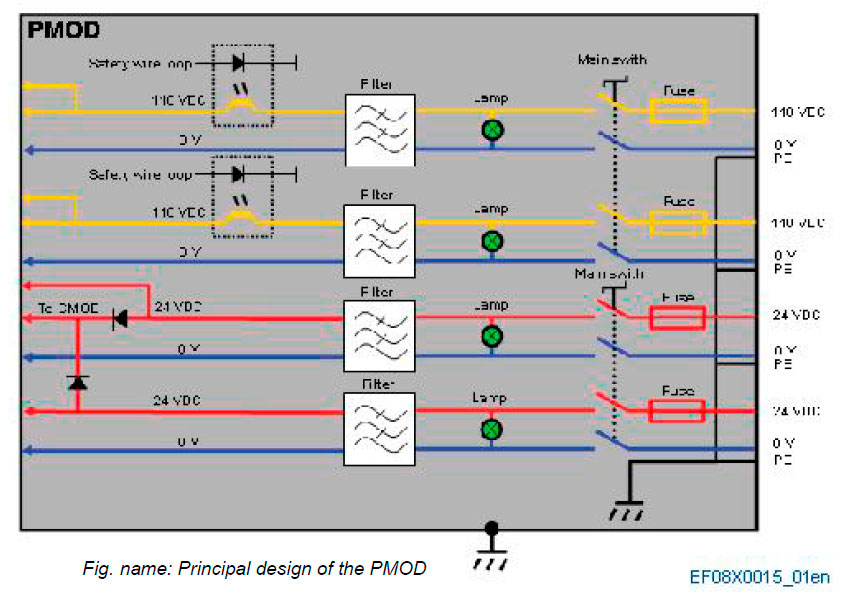

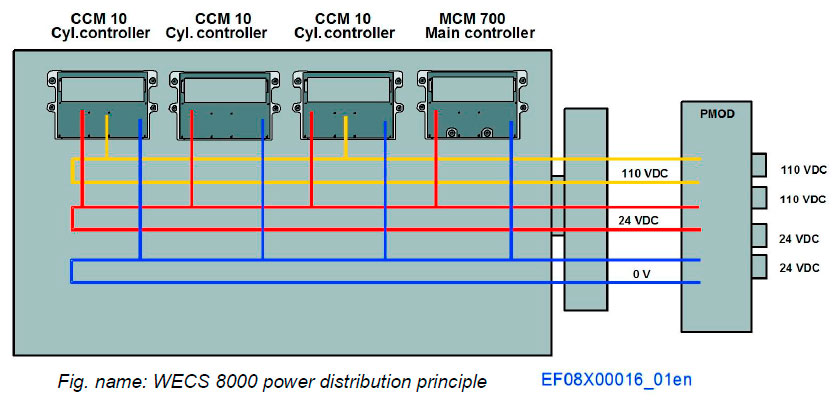

Power distribution and filtration

PMOD CABINET

The power module (PMOD) is a separate cabinet on the engine, that handles the power distribution and filtration within the WECS 8000 system. On the front of the cabinet, there are separate switches for disconnection of the 24 VDC system and the 110 VDC system. Both the main and the back-up voltages for both these DC-systems have green lamps on the front of the PMOD cabinet, for indication of presence of input voltage.

SYSTEM COMPONENTS

- 01 Rectifier

- 02 DC/DC Converter

- 03 EMC Filter

- 04 EMC Filter

INTERNAL CONNECTIONS OF POWER MODULE

The external 24 VDC power supply enters the PMOD via two separate inputs. The two 24 VDC power supplies are via diodes inside PMOD connected to an EMC-filter. There are separate distribution lines from the PMOD to each submodule, all having an individual fuse.

A separate voltage of 110 VDC is in WECS 8000 used as drive voltage for the high energy solenoids (both gas admission valves and pilot fuel inj. valves). The external 110VDC power supply enters the PMOD via two separate inputs. The two 110 VDC power supplies are via diodes inside the PMOD connected together into one single supply. This supply is then via a bi-directional EMC filter and a fuse connected to the cylinder controllers.

WECS 8000 POWER DISTRIBUTION PRINCIPLE

The power supply lines are “looped” around the engine, to provide safe supply in case of a single point wire break. Beside figure which shows this distribution principle.

Other parts of WECS 8000

A CAN REPEATER

This signal repeater extends and isolates galvanically the CAN-bus outside the engine. This external interface is to be connected to an external configuration, calibration & diagnostic tool (PC program), used by authorised personnel only. The transfer rate is 500 kbit/s.

A MEDIA CONVERTER

This converter is used to convert the external communication bus signal (Modbus TCP/IP) from an electrical signal (from LDU) to a signal transferred optically through an optical fibre (to plant automation system). The transfer rate adapts itself according to the device used externally to the engine, and will be either 10 Mb/s or 100 Mb/s.

A CURRENT CONVERTER

A current converter for the actuator. This signal converter module converts the proportional 4-20 mA signal from the main control module to a 0-200 mA signal used by the actuator.

Engine speed measurement

ENGINE SPEED/ANGULAR POSITION MEASUREMENT

- The purpose of this measurement in WECS 8000 is:

- As position feedback to provide accurate gas- & pilot injection timing

- As speed feedback to the internal speed controller

- As speed feedback in internal parameters tables.

- Both the speed and phase measurements are redundant.

- The speed signal pulse train contains a missing pulse, used for determination of engine’s Top Dead Center.

- The purpose of the phase measurement is to determine which of the missing pulses is relevant for TDC of cyl. (A)1.

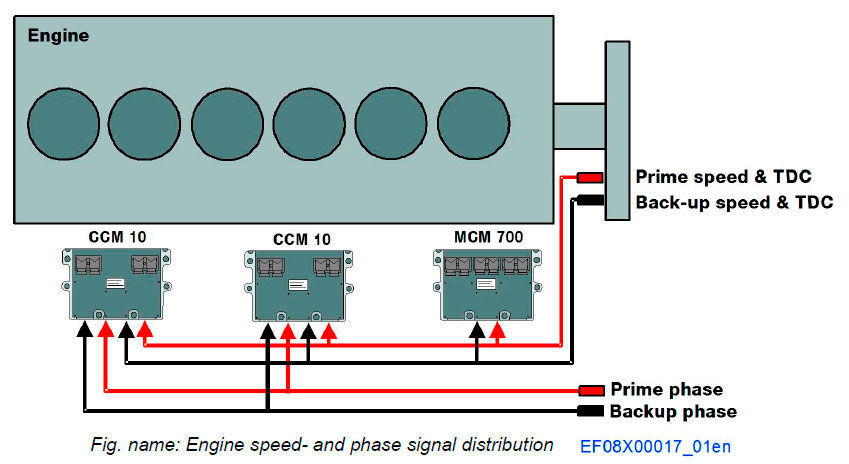

Engine speed measurement

SPEED AND PHASE SIGNAL CONNECTIONS ON ENGINE

The engine speed is measured, based on the signal from two speed sensors. Both speed sensors are connected directly to the main control module (MCM-700), where the speed calculation is carried out in.

For the gas admission- and pilot injection timing processing, the cylinder control modules (CCM-10) need accurate information about the engine speed and engine angular position. Therefore the engine speed- and phase signals are connected to each cylinder control module, for this calculation. These signals are hard-wired to each module, i.e. not transferred as data over CAN.

For redundancy reasons two speed sensors and two phase sensors are connected to each cylinder control module.

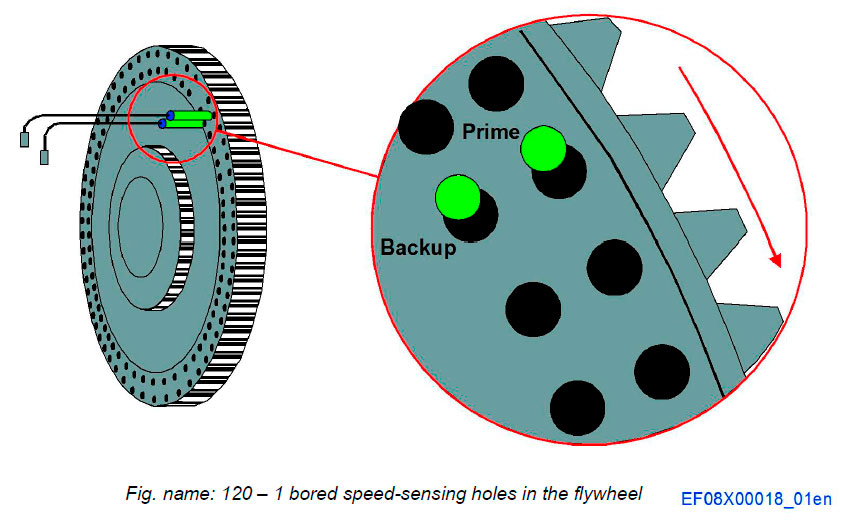

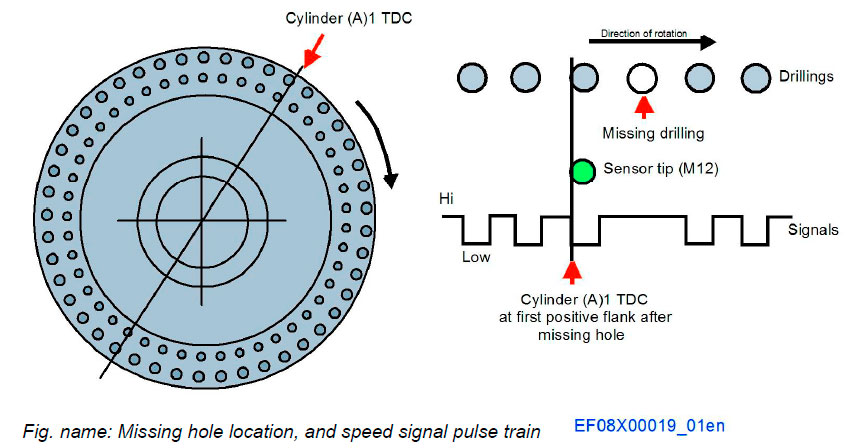

Engine speed measurement

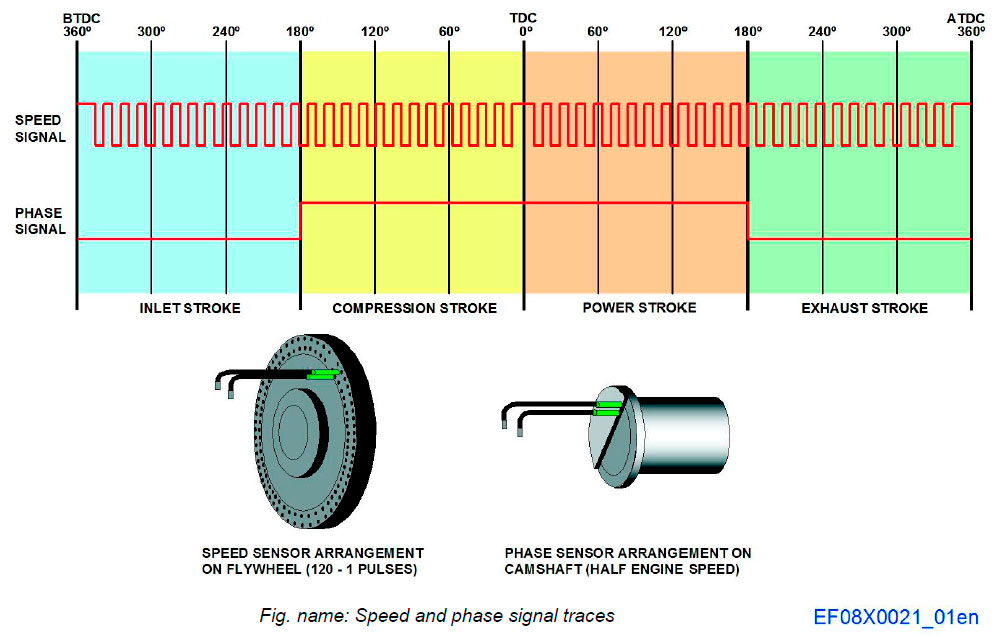

SPEED AND TDC MEASUREMENT

As WECS 8000 must detect the accurate engine angular position, one missing hole is arranged in both speed sensing hole-peripheries on the flywheel, i.e. the pulse train will contain one missing pulse for each engine revolution. The angular locations of the missing holes are such, that the end-edge (= positive electrical flank) of the hole coming after the missing hole, is accurately at TDC (Top Dead Centre) of cylinder (A)1. The speed sensors use separate holes, but the holes are “in parallel”, thus the phase difference between the two signals is negligible. The number of holes is 120 minus the missing one, i.e. 120 – 1.

The sensing gap for these engine speed sensors has to be 2,5 mm ± 0,2 mm. The speed signal pulse train from the two speed sensors will have the shape as in picture below. This signal is connected to all cylinder control modules, as well as to the main control module. The main control module however, has no use of the TDC information, only the speed level.

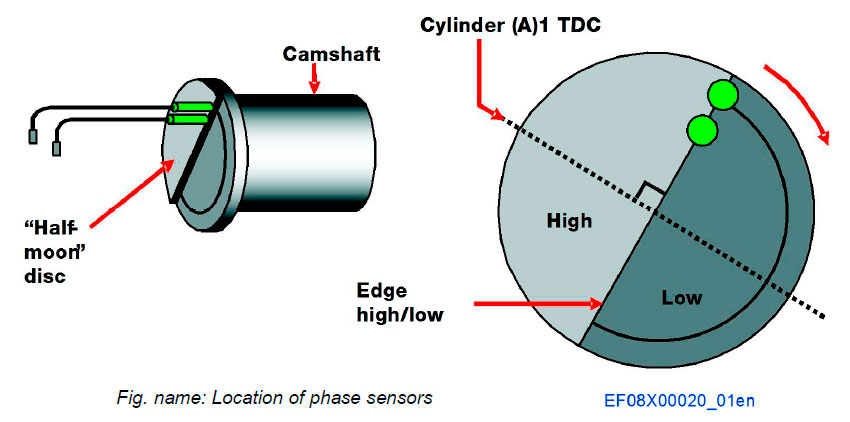

ENGINE PHASE MEASUREMENT

As the engines controlled by WECS 8000 are 4-stroke engines, the crankshaft and thereby flywheel will make two revolutions for one complete engine cycle. To detect which TDC marker signal (missing pulse) belongs to the working phase of cylinder A(1), also engine phase detection is needed. Two phase sensors are provided of redundancy reasons. These sensors are mounted at the driving end of the camshaft of the engine. These sensors are PNP-type proximity switches.

The phase sensors are detecting the “phase” of the engine by means of detecting the position of a “halfmoon” disc, attached to the driving end of the camshaft. This disc is mounted in such a way, that a positive edge (signal going high) will occur 180° BTDC of cyl. (A)1, and will remain high until 180° ATDC for the same cylinder, see picture below. Based on whether the phase signal is high (24 VDC) or low (0 VDC) when the missing pulse comes, WECS can exclude the false missing pulse. Only the missing transition coming while the phase signal is high, is in WECS defined as true.

SPEED AND PHASE SIGNAL TRACES

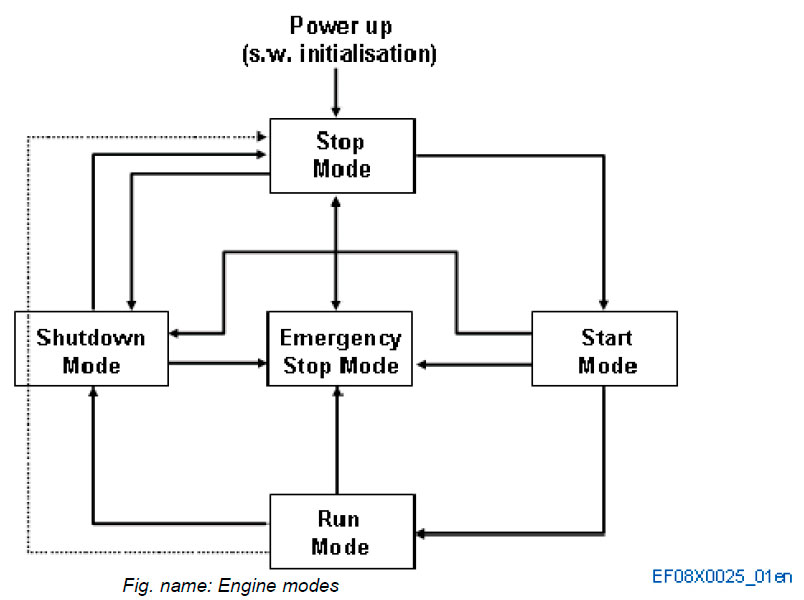

Engine modes

GENERAL

The WECS 8000 engine management system controls and monitors the engine parameters and initiates all required actions in different situations.

These actions can vary from giving an alarm to the operator, to shutting down the engine. Depending on the status of the engine, there are a number of parameters controlled. E.g. when the engine is stopped, it is not valid to create alarms for cooling water pressure. Therefore alarms need to be suppressed under certain conditions. WECS 8000 has because of this and other reasons a number of modes. Different modes have different priority, and the mode changes can occur only according to predefined rules.

Engine control processes during operation

GENERAL

WECS 8000 performs a number of continuous control processes on the engine, when the engine is in run mode. Below, a brief description of each of these processes.

PROCESSES CAN BE DIVIDED INTO CATEGORIES

- Engine speed- and load control

- Gas pressure control

- Gas admission

- Diesel actuator

- Pilot system

- Pilot injection

- Pilot pressure control

- Air/fuel ratio

- Cylinder balancing

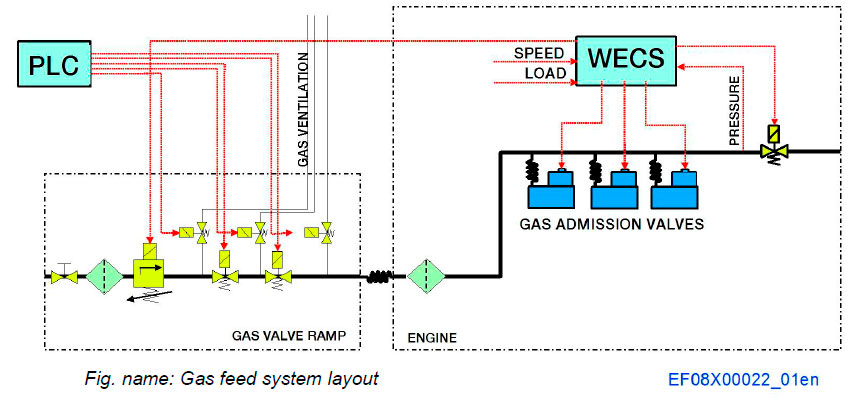

GAS FEED SYSTEM LAYOUT

The gas supplied to the engine passes at first a gas valve unit (GVU). The gas valve unit consists of a filter, temperature/pressure sensors, a pressure regulating valve, safety (shut-off) valves and ventilation valves. The gas supply pressure reference is calculated in the WECS 8000 main control module, and this reference is dependent on the engine load. An electrical pressure reference signal is sent out to the pressure regulating valve.

The actual gas pressure is measured on the engine and compared to the reference pressure. The amount of main gas admitted to each cylinder is controlled by the cylinder individual gas valves, which are actuated by the cylinder control modules. The amount of gas admitted depends on the gas supply pressure and the time the main gas solenoid valve is open (duration). The gas fuel is admitted further away or closer to the TDC by changing the main gas solenoid valve opening moment (timing) in order to obtain an optimal air/gas mixture. The WECS 8000 system uses pre-set (map) values to optimise this mixture during engine operation. Valve duration and timing references are sent to the cylinder control modules from the main control module over the CANbus.

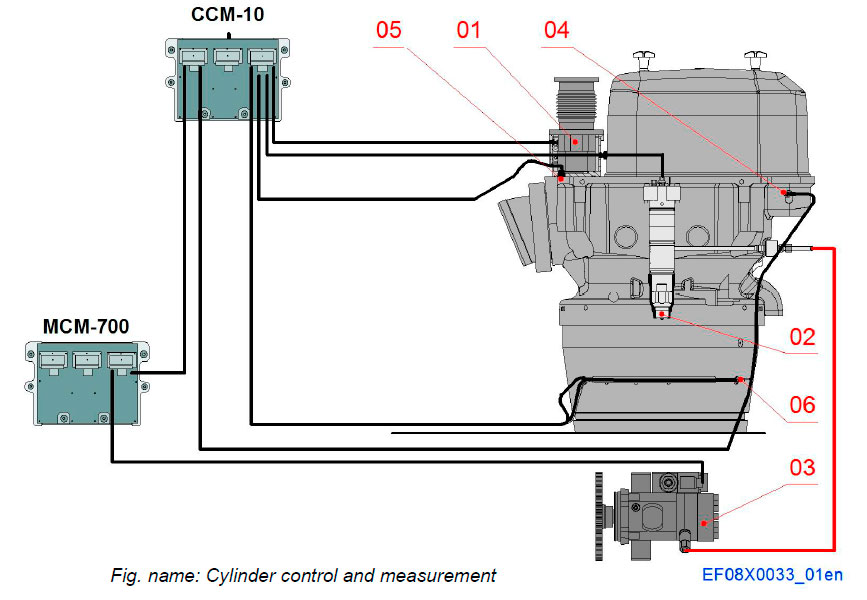

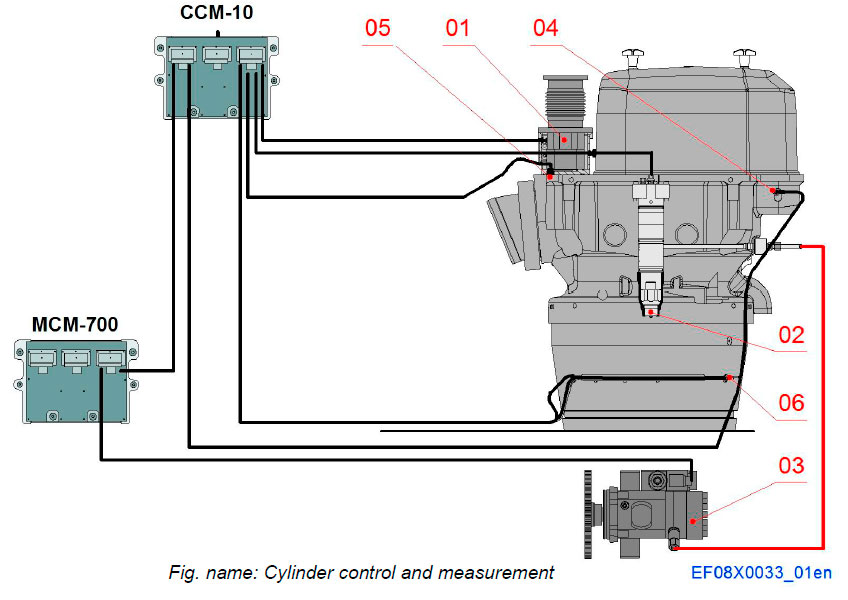

CYLINDER CONTROL AND MEASUREMENTS

An even gas admission duration setting for all gas admission valves will not result in exactly the same gas quantity in all cylinders, due to the geometry of the engine and due to some deviations in the gas valve performance. This slight disparity is handled with the cylinder balancing control.

SYSTEM COMPONENTS

- 01 Main gas admission valve

- 02 Diesel injector with pilot valve

- 03 Pilot fuel pump

- 04 Knock sensor

- 05 Exhaust gas temperature sensor

- 06 Cylinder liner temperature sensor

CYLINDER CONTROL AND MEASUREMENTS

The main control module compares each cylinder’s exhaust gas temperature with the average exhaust gas temperature of the entire engine, and adjusts the duration of the individual gas valves with an offset, in order to minimise the deviation. There are limitations for the maximum adjustment available in order to prevent that possible component failures cause a too rich or too lean gas/air mixture.

The knock control algorithm of WECS 8000 will also affect the gas admission duration.

If the engine is in gas operating mode, and the load level is above approximately 15 % (tuneable) a cylinder knock based control will enable. Light knock in any cylinder will immediately result in a slight reduction of the quantity of gas injected into that cylinder.

In order to maintain the same engine load level, the speed/load controller will automatically increase the gas admission into other cylinders. When the situation normalises in the cylinder, the gas admission will slowly be restored to the original setting.

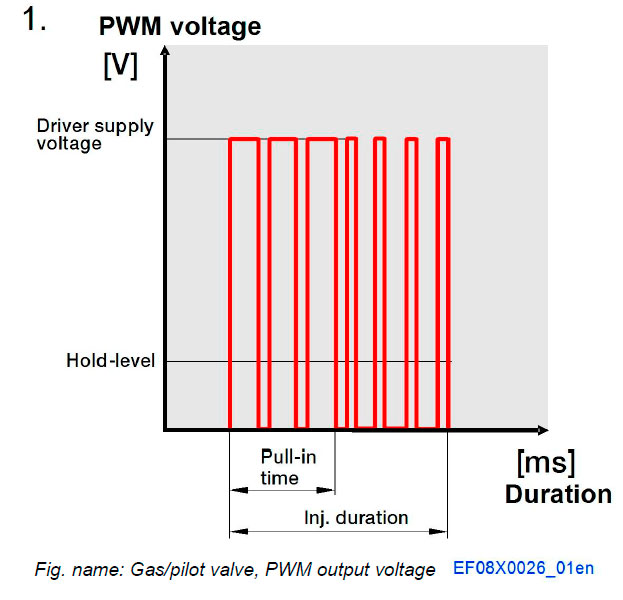

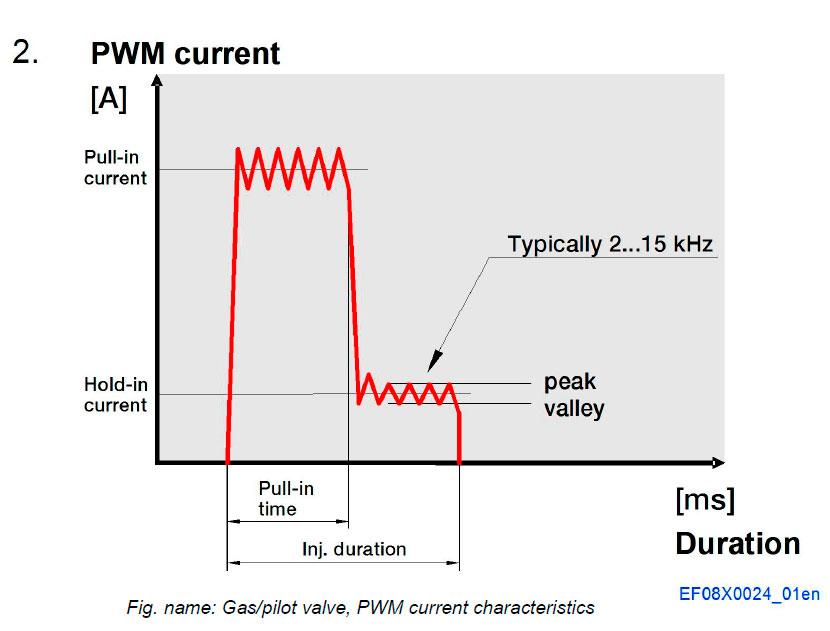

GAS/PILOT VALVE PWM CONTROL

Gas/pilot valve control strategy:

- 110 VDC drive voltage ensures high energy at valve opening.

- The PWM drive signal has envelop shaping to provide fast & consistent valve opening but also low heat generation in the coil.

- The pull-in and hold-in current levels are s.w. configurable.

GAS/PILOT VALVE PWM CONTROL

Gas/pilot valve control strategy:

- 110 VDC drive voltage ensures high energy at valve opening.

- The PWM drive signal has envelop shaping to provide fast & consistent valve opening but also low heat generation in the coil.

- The pull-in and hold-in current levels are s.w. configurable.

Литература

www.wartsila.com