Content

- Lubricating oil system arrangement - Internal

- Lubricating oil system on engine

- Lubricating oil system at free end

- Lubricating oil sump

- Hydraulic jack

- Lubricating oil delivery system

- Splash guards at free end

- Lubricating oil to main moving parts

- Lubricating oil flow at driving end

- Oil flow to intermediate gear wheel bearing

- Oil flow to camshaft driving gear bearing

- Oil flow to camshaft bearing

- Lubricating oil to governor drive and gear wheels

- Oil flow to valve tappets and injection tappet

- Oil flow to valve mechanism and injection valve

- Lubricating oil flow to gear wheels and built-on pumps at free end

- Lubricating oil to turbocharger bearings

- Lubricating oil pump

- Pressure control valve

- Drive gear for lubricating oil pump

- Running-in filter

- Crankcase ventilation system

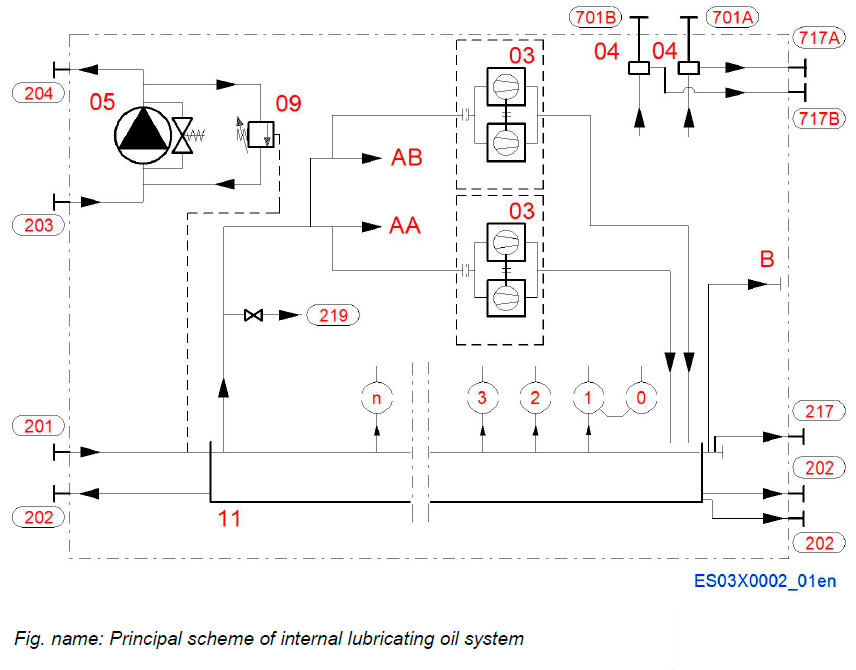

Lubricating oil system arrangement - Internal

System components

- 03 Turbocharger

- 04 Crankcase breather

- 05 Main lubricating oil pump

- 09 Pressure control valve

- 11 Oil sump

Pipe connections

- 201 Lubricating oil inlet (from lube oil filter)

- 202 Lubricating oil outlet (from oil sump, DE, FE)

- 203 Lubricating oil inlet to lubricating oil pump

- 204 Lubricating oil from lubricating oil pump

- 217 Lubricating oil to alternator bearing

- 219 Sample

- 701 Crankcase air vent, A, B-bank

- 717 Crankcase breather drain (to Hot-box), A, -B-bank

- A Lubricating oil to upper parts of the engine, A, B-bank

- B Lubricating oil to camshaft and intermediate gear

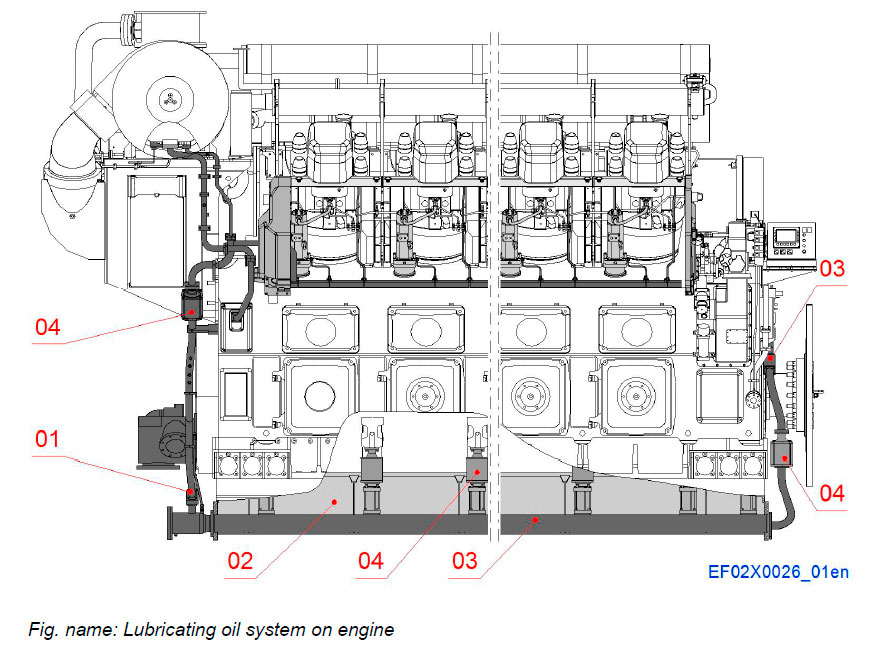

Lubricating oil system on engine

The arrangement on the engine consist of lubricating system at free end, storage system, delivery system, lubricating oil control devices and oil condition monitoring systems.

System components

- 01 Lubricating oil system at free end

- 02 Lubricating oil storage system

- 03 Lubricating oil delivery system

- 04 Running-in filter (for commissioning and maintenance)

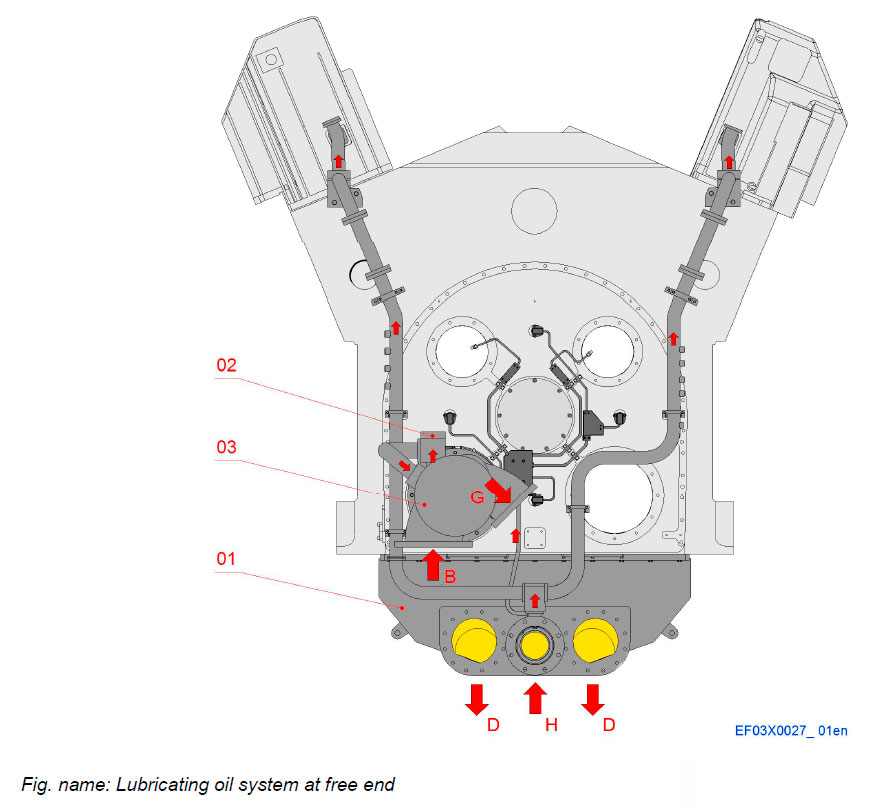

Lubricating oil system at free end

System components

- 01 Oil sump

- 02 Pressure regulating valve

- 03 Lubricating oil pump

Pipe connections

- H Lubricating oil inlet

- D Lubricating oil outlet (from oil sump, DE,FE)

- B Lubricating oil inlet to lubricating oil pump

- G Oil from lubricating oil pump

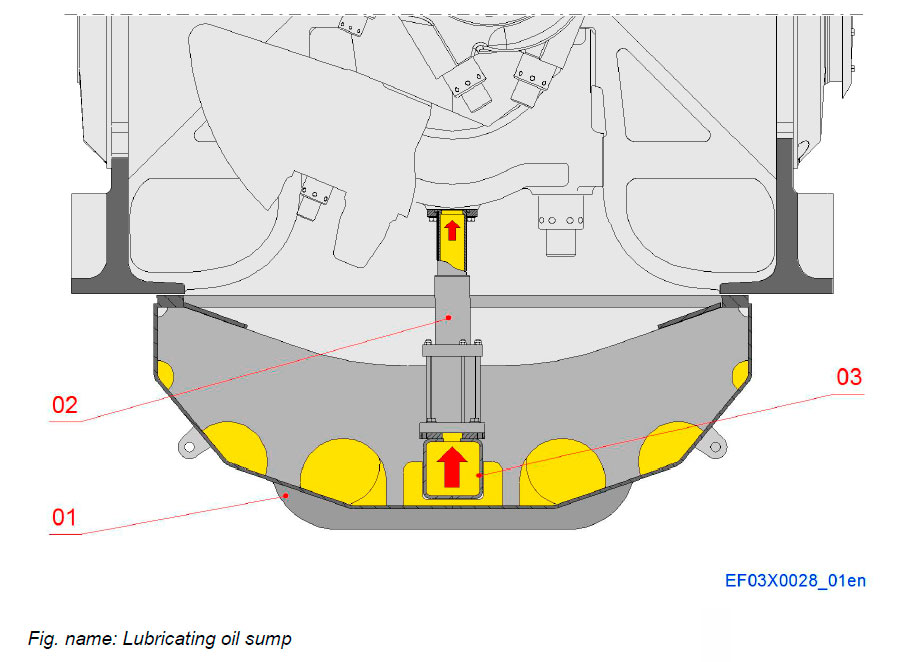

Lubricating oil sump

The oil sump (01) of the engine is a dry sump. After circulation, returned oil is collected in the sump underneath the cylinder block. It has drainage openings situated at the both ends to allow the oil to flow through into a separate system oil tank.

The main function of the dry sump is to collect lubricating oil after circulation through the engine.

System components

- 01 Oil sump

- 02 Hydraulic jack

- 03 Delivery pipe

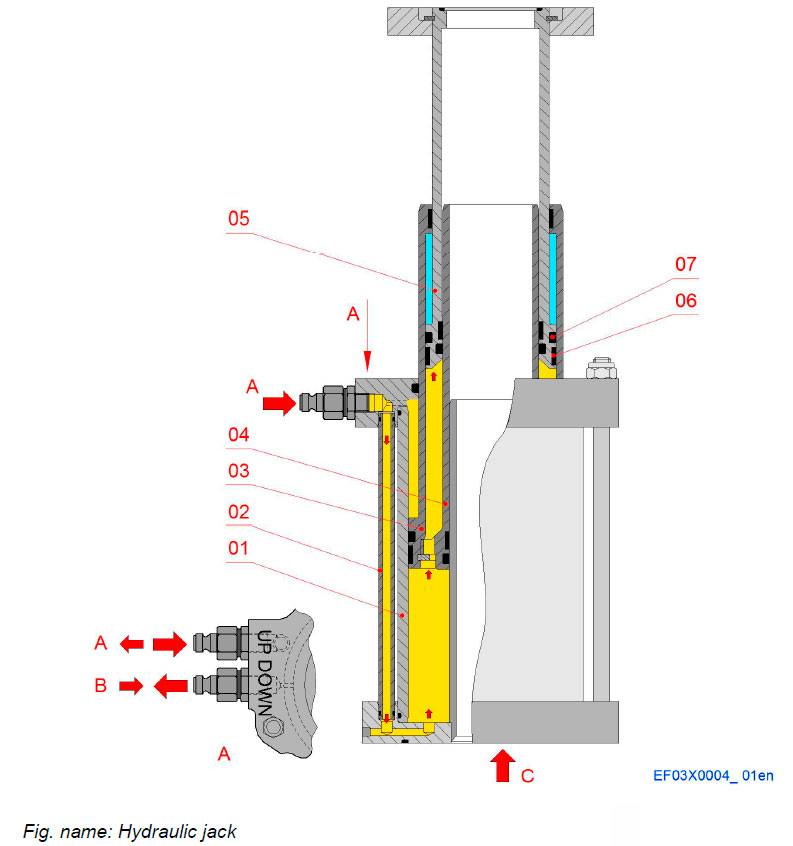

Hydraulic jack

Components

- 01 Cylinder

- 02 Oil pipe

- 03 Piston

- 04 Piston

- 05 Piston

- 06 Support ring

- 07 O-ring

Connections

- A Pressure connection, when lifting

- B Pressure connection, when lowering

- C Lubricating oil inlet

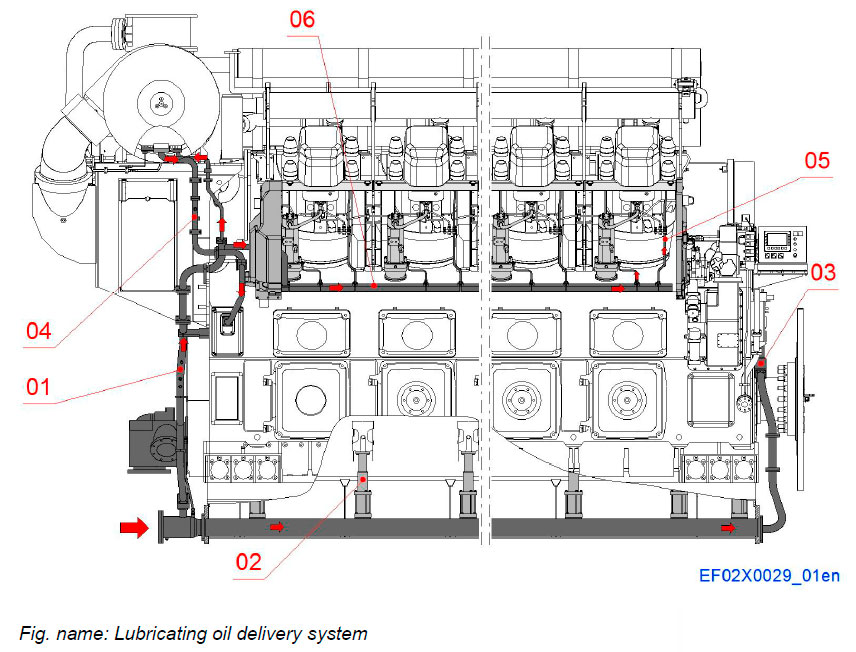

Lubricating oil delivery system

Lubricating oil piping is made in seamless carbon steel and seamless precision tubes in carbon or stainless steel. Lubricating delivery piping can be divided into sub-systems as follows.

System components

- 01 Oil inlet at free end

- 02 Oil piping for main moving parts

- 03 Oil piping at driving end

- 04 Oil piping for turbocharger

- 05 Oil piping for cylinder head

- 06 Oil piping for injection pump, tappets and camshaft bearings

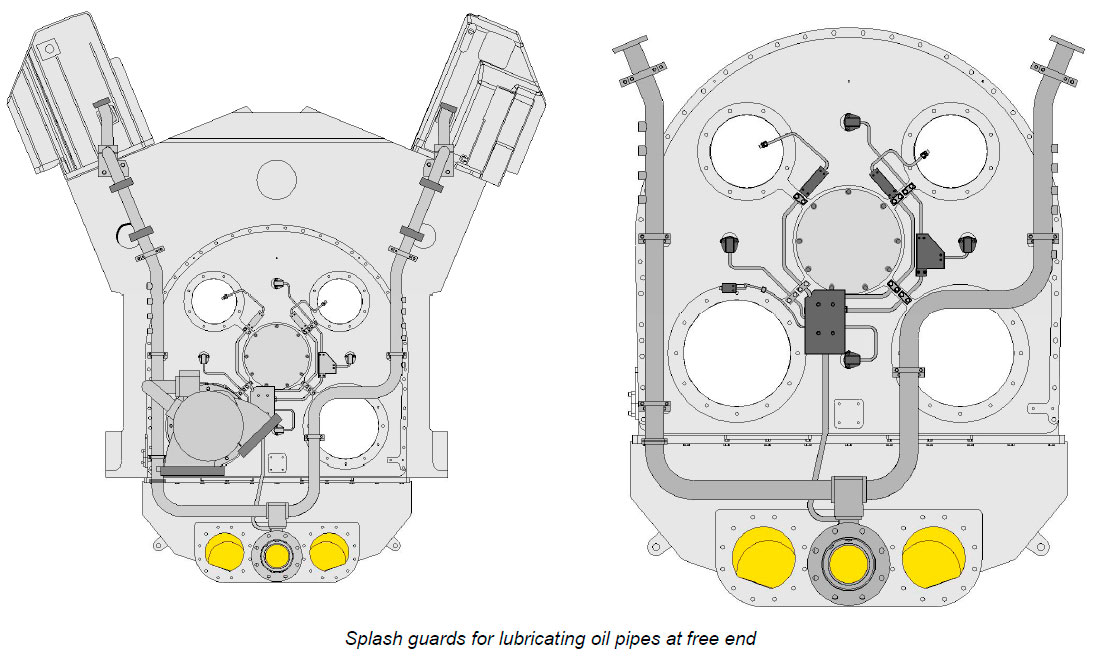

Splash guards at free end

Covers are designed to shield the connections and thus meet the SOLAS requirements (4).

Lubricating oil to main moving parts

OIL FLOW IN THE ENGINE IS DIVIDED TO FOLLOWING LUBRICATING OIL CIRCUITS:

- Lubricating oil to main moving parts.

- Lubricating oil to camshaft bearings and gear wheels at driving end.

- Lubricating oil flow to governor and drive gear.

- Lubricating oil to valves, valve tappet mechanism and fuel nozzle cooling.

- Lubricating oil flow to gear wheels and built-on pumps at free end.

- Lubricating oil to turbocharger bearings.

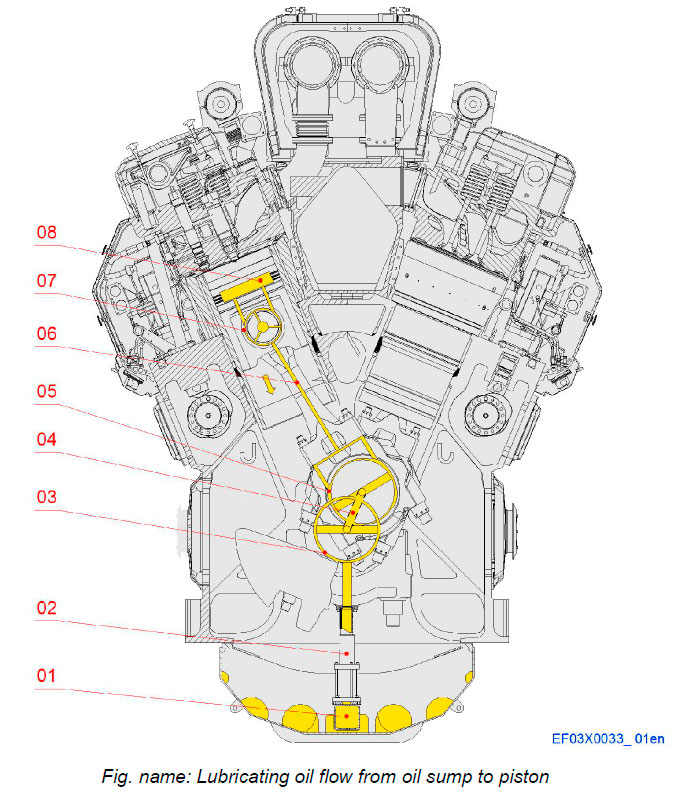

Lubricating oil to main moving parts

From driving end oil flows to distribution channel at the bottom of the oil sump (01). From distribution channel oil flows through hydraulic jack (02) to main bearings (03), through crankshaft (04), to connecting rod bearings (05), up through connecting rod (06) to gudgeon pin bearings (07) and further to piston skirts cooling space (08).

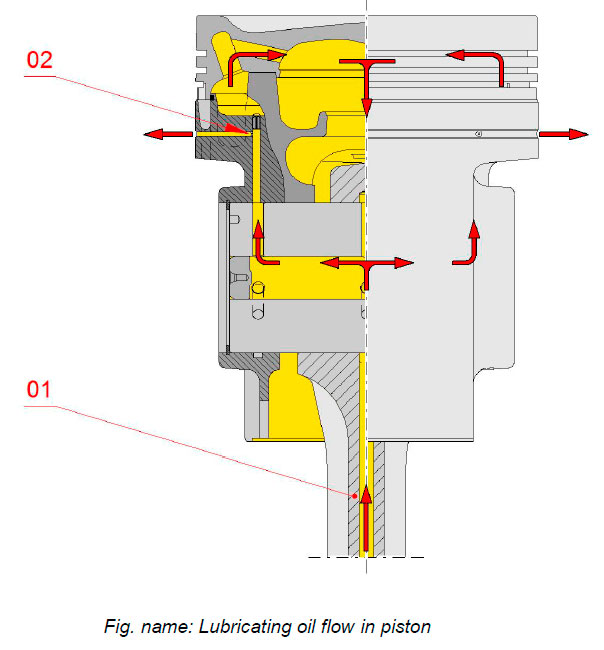

LUBRICATING OIL FLOW IN PISTON

Part of the lubricating oil through connecting rod (01) flows out from piston skirt through the special nozzles (02) to cylinder liner, forming an oil film between piston and cylinder liner surfaces. From the cylinder liner oil is drained back to oil sump.

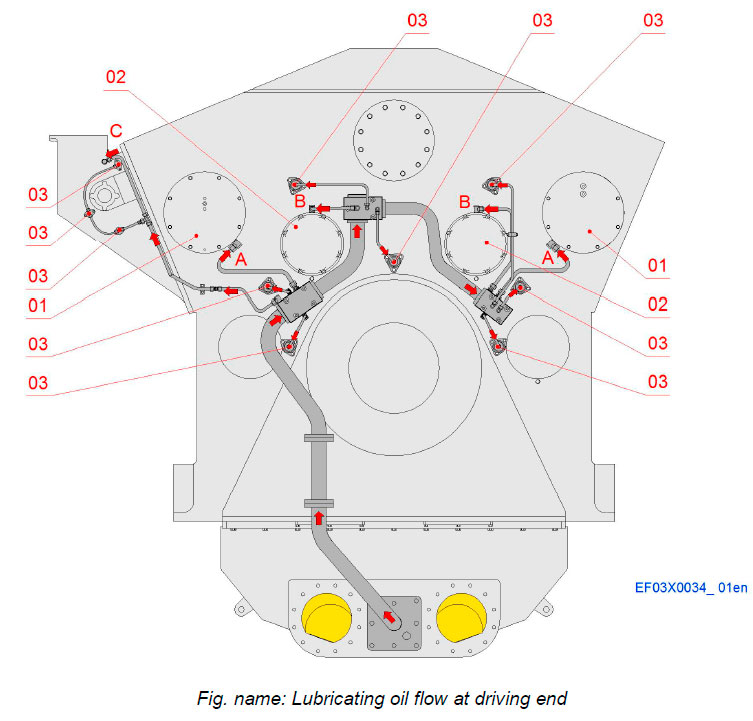

Lubricating oil flow at driving end

The oil circuit consists of lubricating oil pipes and oil channels for camshaft drive gears and intermediate gears.

Part of the lubricating oil flow is branched for lubrication of the gear wheels by special lubricating oil nozzle pipes (03). The nozzle pipes include small nozzle holes where out coming lubricating oil jet lubricates the gear wheels.

System components

- 01 Cover for camshaft

- 02 Cover for intermediate gear

- 03 Lubricating nozzle for gear

Pipe connections

- A Lubricating oil inlet to camshaft drive gear bearing

- B Lubricating oil inlet to intermediate gear bearing

- C Lubricating oil supply to governor drive and gears

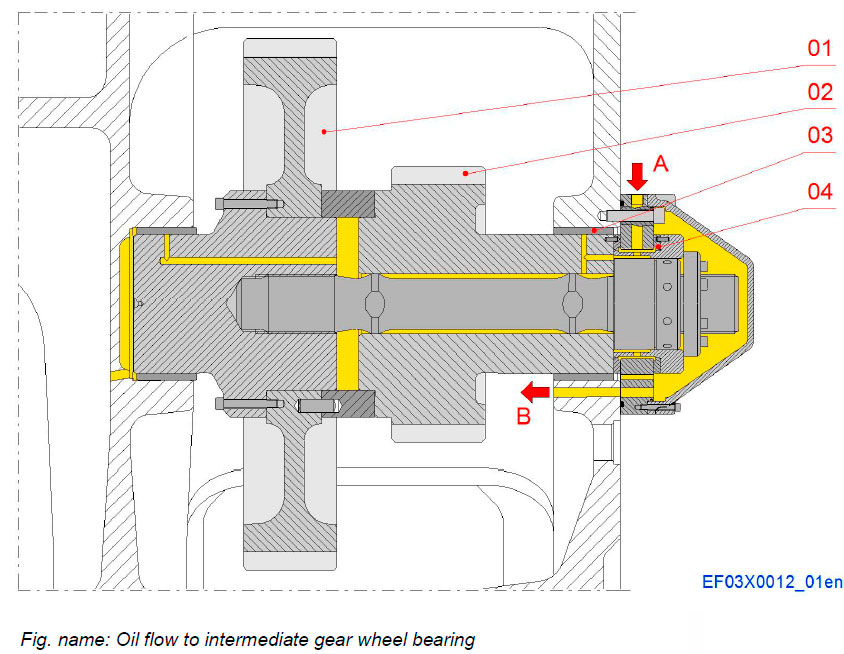

Oil flow to intermediate gear wheel bearing

From lubricating oil piping oil flows through channels of cover to thrust bearing and further to intermediate gear. Through channels of intermediate gear oil flows to bearings and back to oil sump.

System components

- 01 Bigger intermediate gear wheel

- 02 Smaller intermediate gear wheel

- 03 Intermediate gear bearing

- 04 Thrust bearing

Connections

- A Oil flow to bearing

- B Oil drain to sump

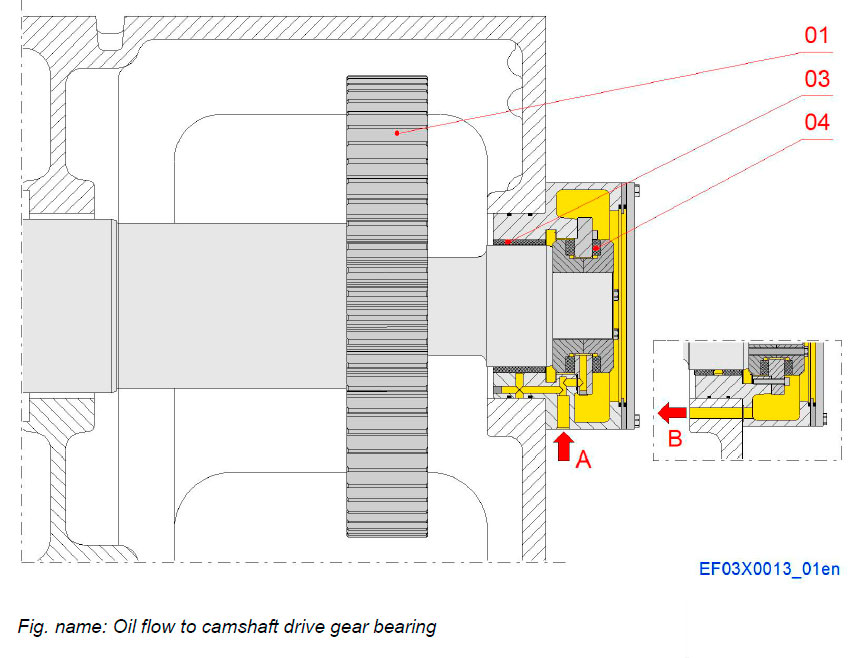

Oil flow to camshaft driving gear bearing

From lubricating oil piping oil flows through channels of cover to bearing and camshaft end. Through channels oil flows back to oil sump.

System components

- 01 Camshaft driving gear wheel

- 03 Camshaft driving gear bearing

- 04 Thrust bearing

Pipe connections

- A Oil flow to bearing

- B Oil drain to sump

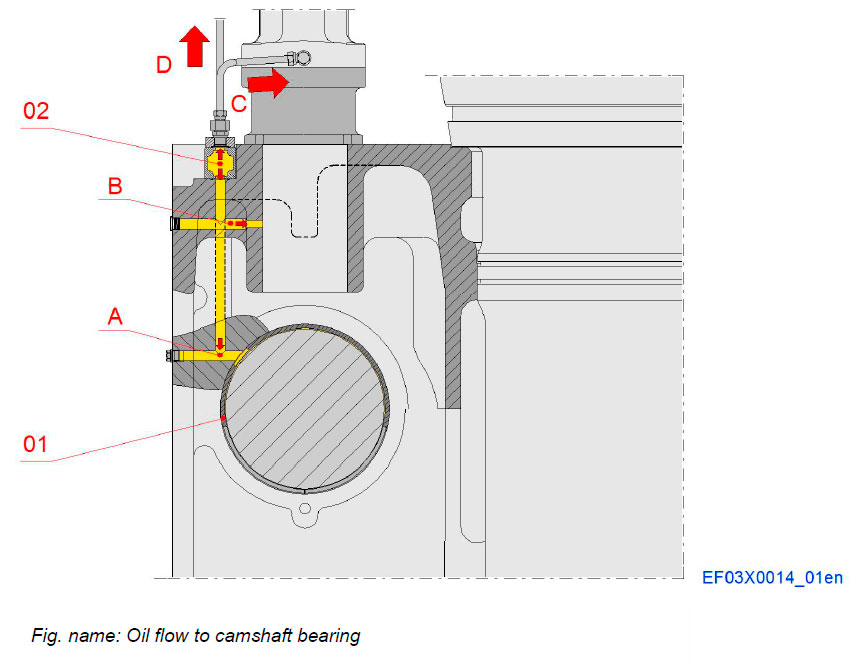

Oil flow to camshaft bearing

From the aluminium profile of delivery line the lubricating oil is branched for lubrication of the camshaft bearing, for injection pump, for lubrication of tappets and valve mechanism. Further on, oil is branched for cooling of the injection valve.

System components

- 01 Camshaft bearing

- 02 Lubricating delivery line in Hot-box

Connections

- A Oil flow to camshaft bearings

- B Oil flow tappets

- C Oil flow to injection pump

- D Oil flow to cylinder head

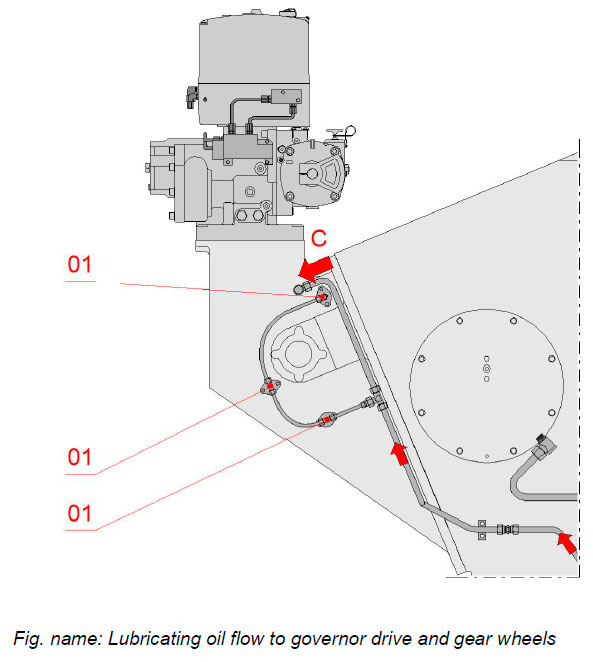

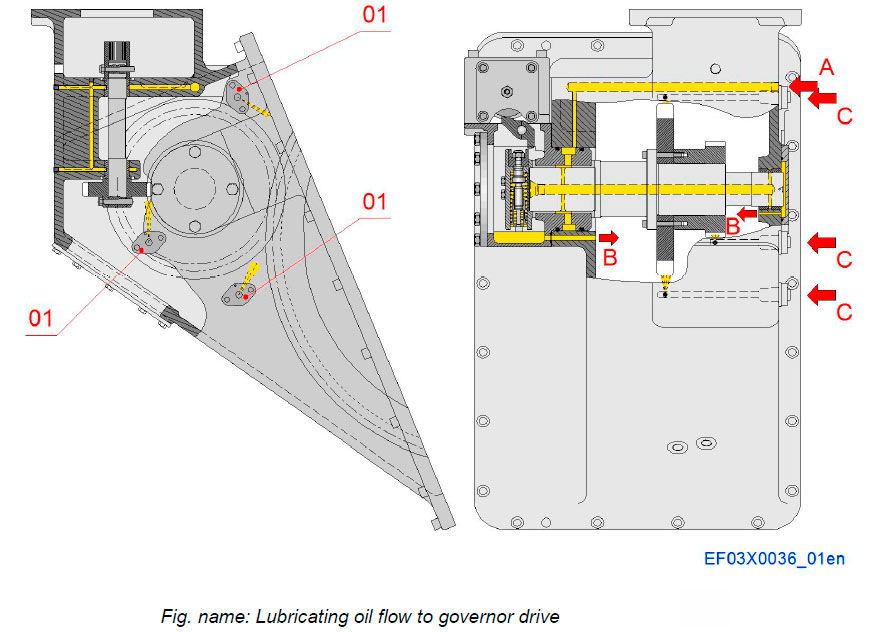

Lubricating oil to governor drive and gear wheels

The governor drive bearings and drive gears are lubricated by the engine internal lubricating oil system. The system consists of the suction oil pipe connected to the governor drive housing, oil pipes for the drive bearings and lubricating oil nozzle pipes for drive gears.

Oil is supplied by special oil nozzle pipes from the oil circulating system to the drive gear wheels and bearings of governor drive. The nozzle pipes include small nozzle holes from where a forced lubricating oil jet lubricates the gear wheels.

System components

- 01 Lubricating oil nozzle for gears

Connections

- C Lubricating oil inlet to governor drive

The oil from the engine internal lubricating oil system flows through internal channels of governor drive to bearings and drains to sump.

Lubricating oil nozzles lubricate gear wheels.

System components

- 01 Lubricating oil nozzle for gears

Connections

- A Oil flow to bearings

- B Oil drain to sump

- C Oil flow to nozzle

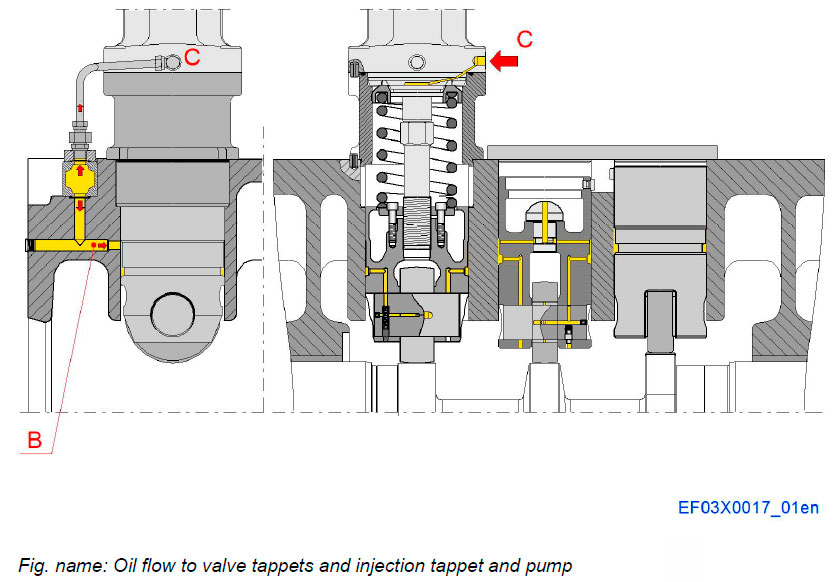

Oil flow to valve tappets and injection tappet

From the aluminium profile manifold in the Hot-box on the engine block the lubricating oil is led for tappets assembly through oil channels of engine block.

Lubrication of injection pump is arranged via lubricating pipe connection.

After circulation the oil then returns to the oil sump.

Connections

- B Oil flow to injection tappets and valve tappets

- C Oil flow to injection pump push rod

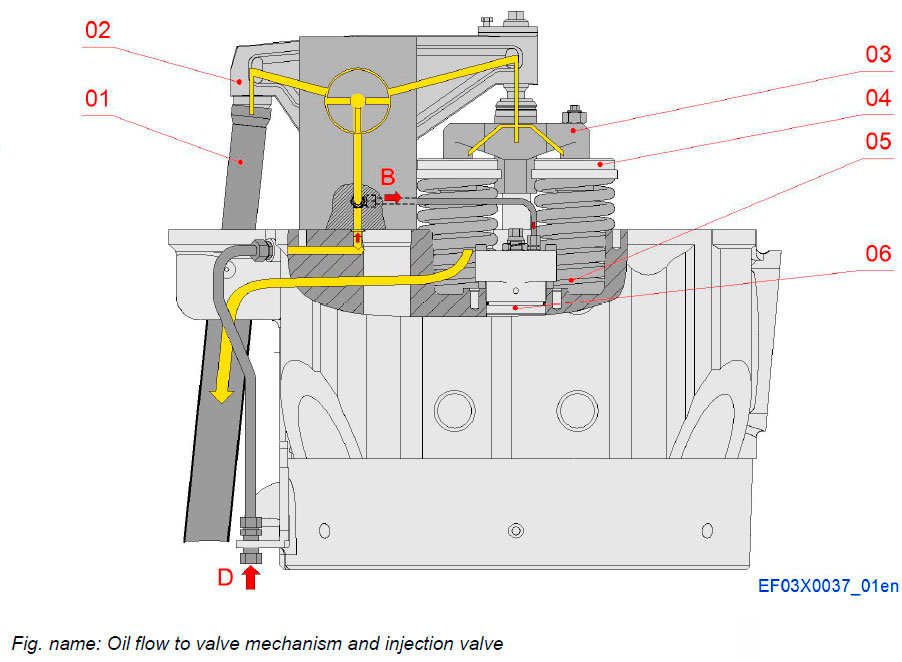

Oil flow to valve mechanism and injection valve

The oil flows to the cylinder head through a connection on the side of the cylinder head. Inside of the cylinder head oil flows through bore. And then continues up through the internal channels in the rocker arms arrangement, through the yoke pins to the top of the valves.

The oil flow for the injection valve cooling is arranged via oil pipe to the top of valve body where oil flows to the nozzle end and then returns to top of the cylinder head. The oil then is drained via the push rod covering pipe through the valve tappets assemblies and back to the oil sump.

System components

- 01 Push rod

- 02 Rocker arm

- 03 Yoke

- 04 Valve rotator

- 05 Valve and valve guide

- 06 Injection valve

Pipe connections

- B Oil flow to injection valve cooling

- D Oil inlet connection

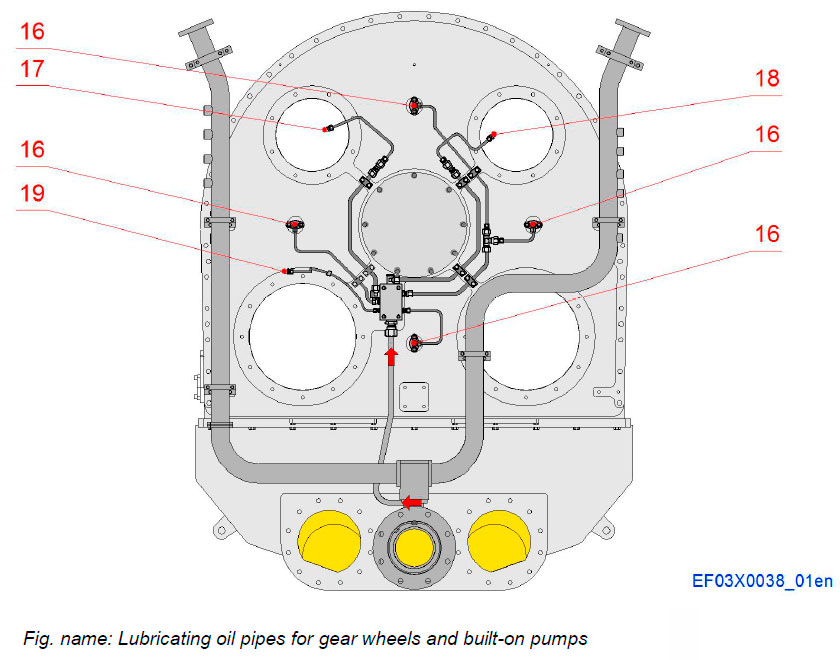

Lubricating oil flow to gear wheels and built-on pumps at free end

The system consists of the suction oil pipe from the oil inlet, oil pipes for the built-on pump bearings and gear wheels, and lubricating oil nozzle pipes.

Oil is supplied by special oil nozzle pipes from the discharge side of the lubricating oil pump to the drive gear wheels of the crankshaft and built-on pumps.

The nozzle pipes include small nozzle holes through which a forced lubricating oil jets feed the gear wheels.

System components

- 16 Lubricating nozzle for driving gear

- 17 Lubricating oil inlet for LT-water pump

- 18 Lubricating oil inlet for HT-water pump

- 19 Control pressure from delivery piping

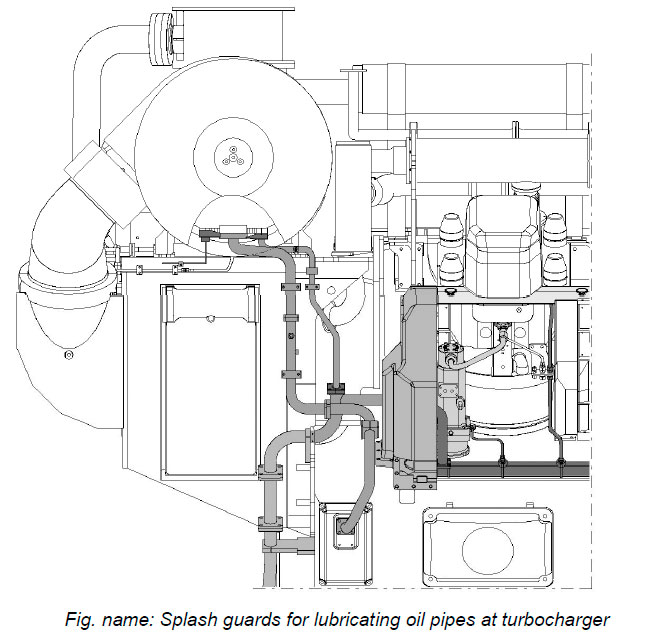

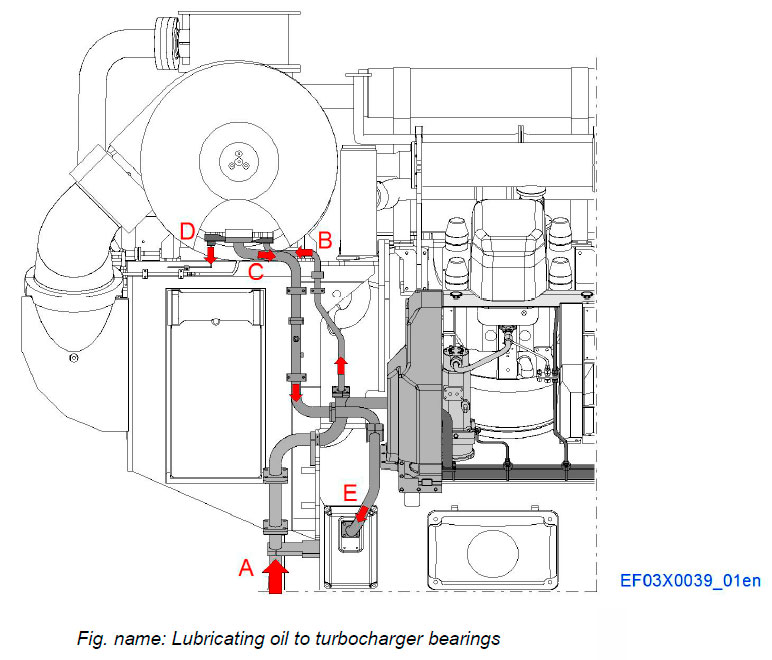

Lubricating oil to turbocharger bearings

Pipe connections

- A Lubrication oil delivery

- B Lubricating oil to turbocharger

- C Lubricating oil outlet

- D Lubricating oil to pressure switch

- E Lubricating oil drain to sump

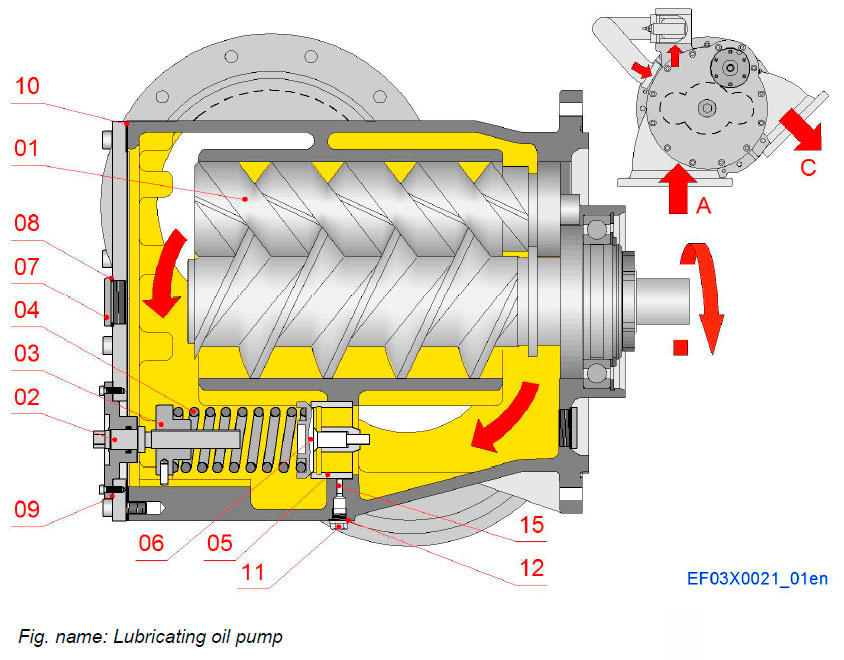

Lubricating oil pump

The lubricating oil pump is a screw pump with three screw spindles, driving and two idler spindles. The pump is dimensioned for actual lubricating oil viscosity.

The working parts of the pump are the three screw spindles, which rotate in the surrounding casing. The liquid moves axially when the screws rotate and is forced hereby creating a pumping action.

The pump has an built-in pressure relief valve, which functions as a safety valve for the pump. The pump lubrication is supplied by the pumped lubricating oil.

The pressure relief valve is designed for the maximum lubricating oil flow of the pump. When the pressure exceeds the adjusted values on the pressure side, the valve cone lifts from the seat and the lubricating oil circulates into suction side of the pump casing. The opening pressure is adjusted by compressing the valve spring with the adjusting screw at the factory.

Pressure control valve of lubricating oil system is integrated into pump housing.

Components

- 01 Set of spindles

- 02 Adjusting screw

- 03 Spring plate

- 04 Valve spring

- 05 Valve seat

- 06 Valve cone

- 07 Screw plug

- 08 Sealing ring

- 09 Gasket

- 10 Gasket

- 11 Screw plug

- 12 Sealing ring

- 15 Threaded pin

Connections

- A Suction connection

- C Pressure connection

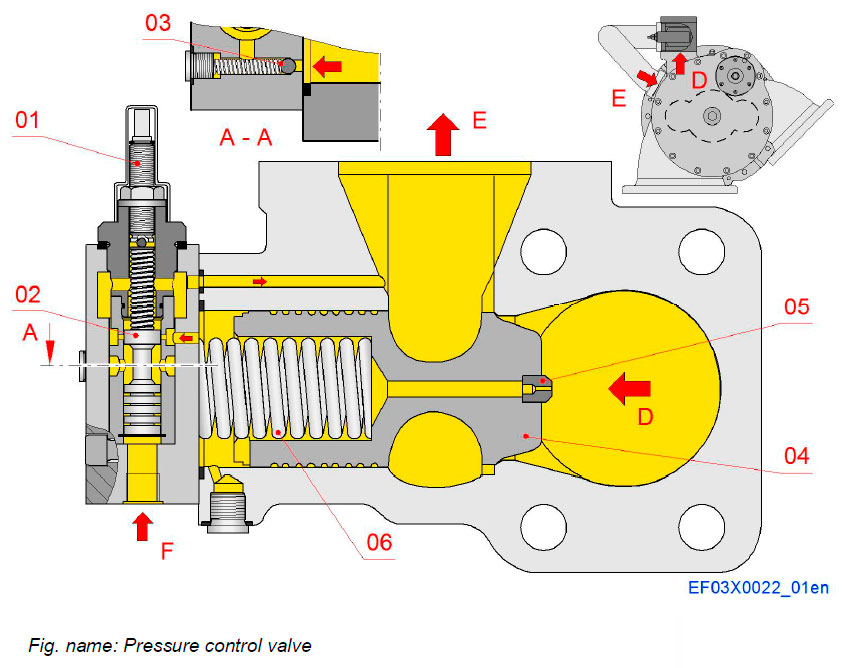

Pressure control valve

The lubricating oil system is equipped with a pressure regulating valve to maintain the oil at a constant pressure to the engine lubrication oil feed pipe under variable conditions (pressure changes after feed pump, pressure drop changes in coolers and filters etc.).

If, for some reason, the pressure should increase strongly in the pressure side, safety valve (03) will open and admits oil to pass to the regulating piston (02). This serves as a safety valve.

Components

- 01 Adjusting screw

- 02 Pilot control piston

- 03 Overload safety valve

- 04 Main regulating piston

- 05 Orifice

- 06 Spring

Connections

- D Pressure connection

- E Outlet connection

- F Control pressure

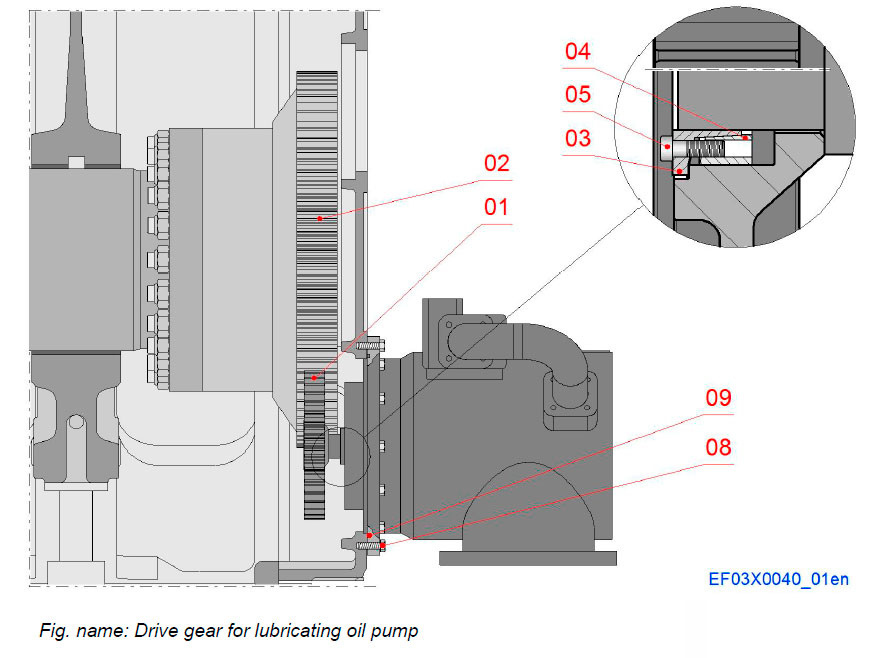

Drive gear for lubricating oil pump

The lubricating oil pump is driven by drive gear wheel at the end of crankshaft, which rotates pump mechanism. Gear wheel of pump is mounted with clamping rings.

Pump is positioned correctly into pump cover with flange of pump and fastened by screws.

Components

- 01 Gear wheel

- 02 Driving gear wheel

- 03 Clamping ring, outer

- 04 Clamping ring, inner

- 05 Screw

- 08 Screw

- 09 Sealing ring

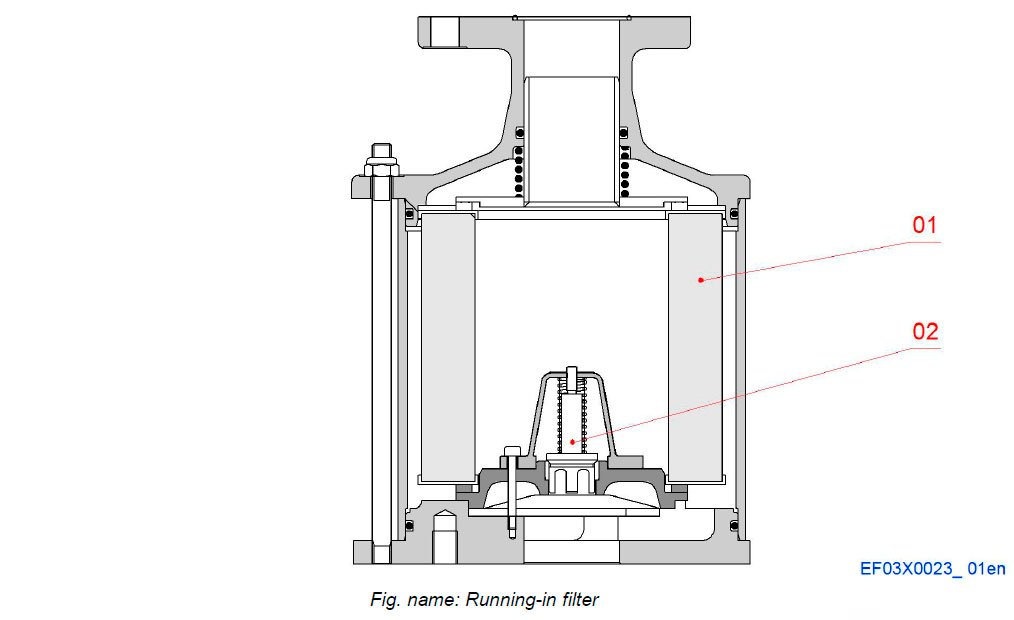

Running-in filter

All engines are provided with full-flow filters. The filters are used only during running-in and at the first start-up of the installation.

The oil flows through the filter insert and dirt particles are collected to filter insert. A safety valve is built into the middle of the lower end flange. This safety valve opens if the pressure rises too much and allows the oil to pass through.

It is recommended to use running-in filters after certain maintenance operations, such as major engine repairs and oil system maintenance or repair.

The filters are usually removed by the installation personnel.

Components

- 01 Filter cartridge

- 02 Safety valve

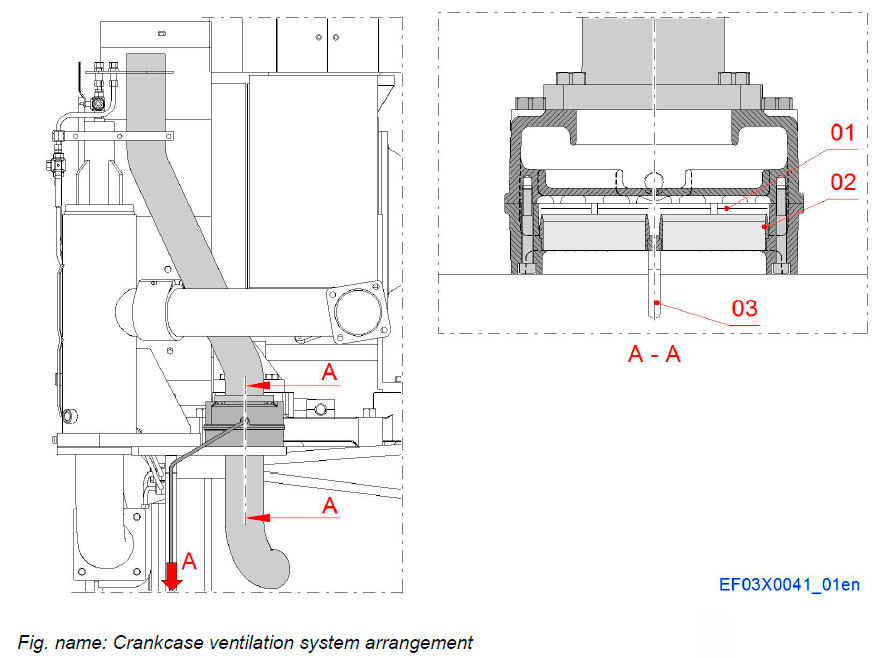

Crankcase ventilation system

There is always an amount of vaporized oil in the crankcase and it has to be ventilated out from the engine. Vaporized oil is led out by the ventilation pipe mounted on the engine block.

Inside the ventilation pipe there is a valve plate where vaporized oil is condensed.

Condensed oil drains back to the crankcase and the remaining "dry" vaporized oil continues further up the pipe and out from the engine.

System components

- 01 Valve plate

- 02 Base for breather valve

- 03 Oil lock for breather

Pipe connections

- A 717 Crankcase breather drain

Литература

www.wartsila.com