The Exhaust Valve of a 2 stroke marine engine is centrally installed over the top of cylinder head to allow all the exhaust generated inside the chamber during combustion process to be transferred to the exhaust trunk.

The exhaust valve can be divided in 3 important parts:

Exhaust valve body: The outer body of the exhaust valve comprises of bores for passage of cooling water, guide for spindle of valve, cage for valve seat and other attachments for valve operation. It also comprises of compartments for power piston, which is operated by hydraulic and air pressure.

The body generally is made up of cast iron, which has good manufacturing property along with strength. The valve guide is made up of perlite cast iron.

Exhaust valve with spindle: The valve with spindle can be separated from the body in order to grind and recondition after a period of time or when required.

The spindle is provided with rotary vanes attached above the valve in the stem. When exhaust gases pass through these vanes, it rotates the valve to avoid local distortion of the valve and valve seat.

The modern age exhaust valve is made from nickel-based alloy, precipitated hardened steel, austenitic steel or siliconchrome steel.

For big engines, normally Nimonic spindle and a steel bottom piece with a surface-hardened seat to match the greater hardness of the Nimonic spindle at high temperatures are used.

The face of the valve is stellite coated to increase thermal resistivity.

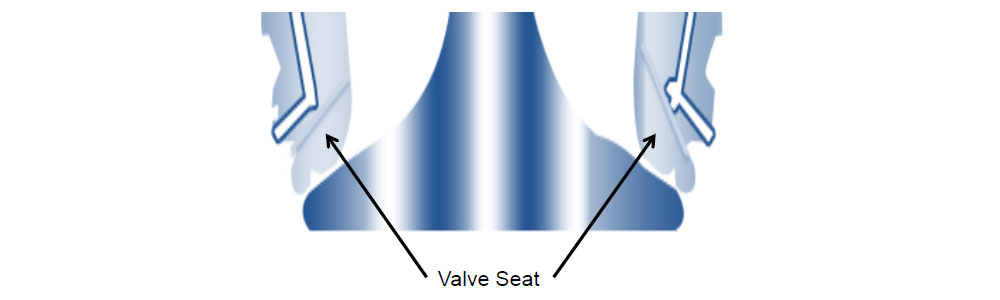

Exhaust Valve Seat: The Exhaust valve seat is a detachable part, which can be reconditioned or replaced in case of damage. The seat is stellite coated as it is also prone to high temperature wear.

Types of Exhaust Valves

With development of engines, the exhaust valves have also been enhanced in terms of construction, mode of operation and reduction in maintenance period.

Following are the types of exhaust valves used in a 2 stroke marine engine:

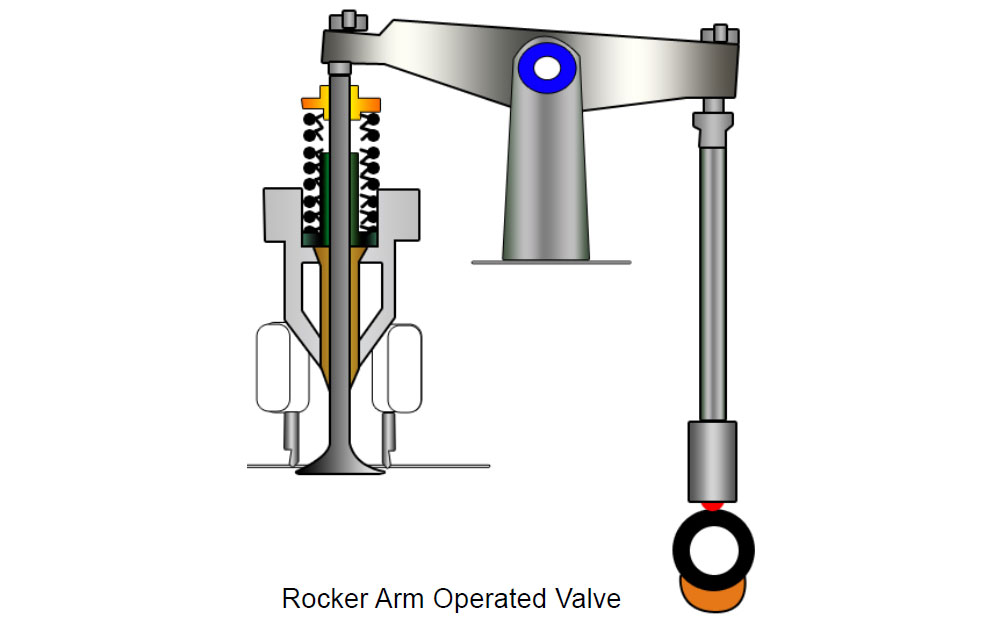

Rocker arm and push rod operated valve: Old engines (MAN and SULZER) used rocker arm and push rod to operate the exhaust valve. Small size engine with small size exhaust valve were good in operation with such arrangement.

With increase in size of the engine and cylinder bore, this mechanical operating system was not efficient and generated many problems.

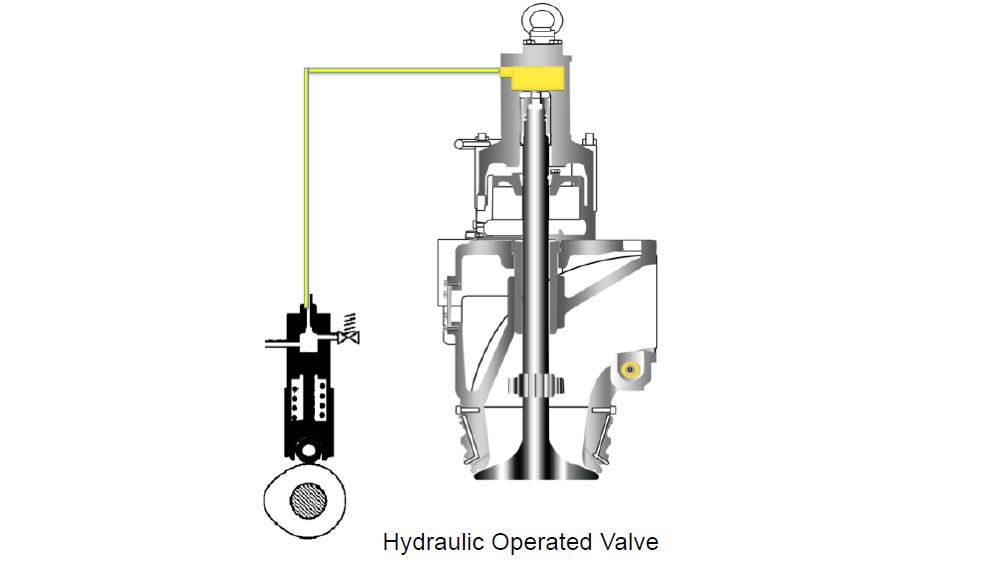

Hydraulic operating exhaust valve: The rocker arm arrangement was replaced by hydraulic operating system with no tappet and no tappet clearance to be set. With better operating condition and reduced wear, this system is now used in modern marine engines.

Hydraulic operated exhaust valve with mechanical spring: In some exhaust valves, springs are fitted on top of the hydraulic actuation system. The spring generates the additional required force to ensure positive closing of the valve.

Hydraulic operated exhaust valve with Pneumatic spring: In modern engines, the mechanical spring is replaced by pneumatic spring system. This eliminates the problems of valve bounce and spring breakage.

“W” seat exhaust valves: The latest technology from MAN engines with “W” shape seat profile reduces the burnout of valve and valve seat.

Problems in Exhaust Valve

Some of the common problem in exhaust valve are:

- High temperature corrosion of complete valve and valve seat

- Reduction in the valve lift

- Failure of spring

- Erosion of valve and valve seat

- Bending of valve spindle

- Localised burning of valve and valve seat

- Breakage of valve rotater vanes

- Carbon or molten salt deposits in the exhaust passage and valve surface

- Poor cooling of valve cage

- Reseating failure leading to exhaust leakage

- Banging of valve while closing

One of the most common problems in exhaust valves is knocking while running. Following are some main resons for the same –

Deficiency in the Oil System: The knocking can be due to problems arising in the hydraulic oil system which is responsible for the operation of the valve:

- Air in oil or air being drawn at pump suction side

- Supply pressure of oil is too low

- Oil temperature is high leading to reduction is viscosity.

Deficiency in the air system:

- Incorrect spring air supply pressure

- Defective or malfuctioning drain valve in the air chamber

- Defective or malfuctioning of safety valve in the air chamber

Leakage in hight pressure oil system:

- Wrongly adjusted or defective throttle screw

- Oil cylinder piston ring in the exhaust valve leaking

- Oil cylinder safety valve on cam side leaking

- High pressure pipe is damaged

- Leakage in vent valve at the top

Inspection of Exhaust Valve

Check the following while inspecting exhaust valves:

- Before fitting the exhaust valve, check the operation of “closing” by lifting the valve with engine room crane. Once it is clear off the ground, the valve will be in the open position. Connect air hose with compressed air supply to pneumatic piston inlet and open the air supply. This will close/ shut the valve.

- Once the valve is closed, shut off the air supply and keep it in that postion for 15 minutes and check that it does not open. This means that the air piston does not have leakage.

- Open the vent plug screw located on the air cylinder- this will bring the valve in open condition

- Check for burnout marks in the valve face and seat

- Check for cracks and breakage of rotary vanes attached to the valve spindle

- Check scoring mark in the valve seat and valve face. This indicates valve rotator is not working and is leading to localised burning or leakage

- Check condition of thrust pads in the exhaust valve

- Check the actuator for marks on the sealing surface

- Check the surface of hydraulic pipe connecting face for surface deformation, indicating leakage or incorrect tightness

Latest Technology and Development

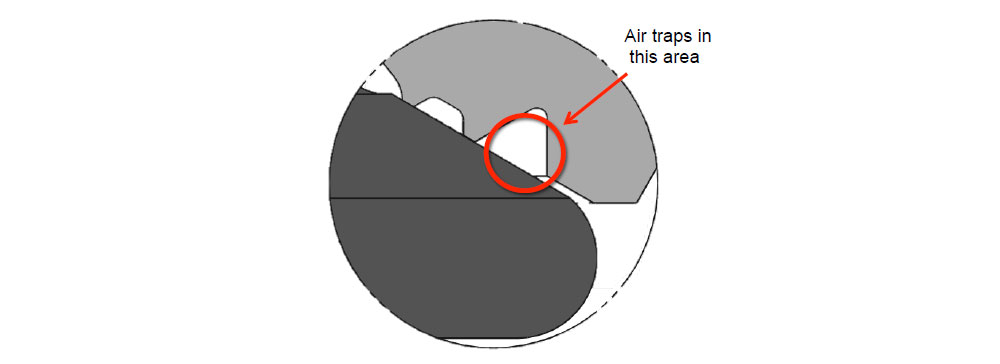

“W” Seat- The seat of the valve is made in “W” shape, wherein air gets trapped during the compression stroke and provides a cooling effect, reducing thermal stresses.

It is made of solid low alloy steel prepared by induction hardening. The main advantage of this seat is that it’s cheaper to manufacture and provides a Time Between Overhaul (TBO) of approx- 30,000 hrs (15 years).

Dura Spindle: In this type of exhaust valve spindle, reselient ni-cr alloy welded on stainless steel spindle and hardened with ten tonnes of force in special rolling process to 500HV is used. This gives better hardness and ductlility than stellite or nimonic coated spindles. The TBO is 50% more than conventional spindles.

Variable Exhaust Valve Closing: In this system the valve closing timing is altered without disturbing the lift of the valve.

This is done to optimize the exhaust valve operation over the normal load range, where the closing point of the exhaust valve is changed over 70-85% of MCR.

During Variable Exhaust Closing operation if the exhaust valve is closed early, it means that the compression stroke of the piston is increased. This will lead to higher compression pressures and temperatures.

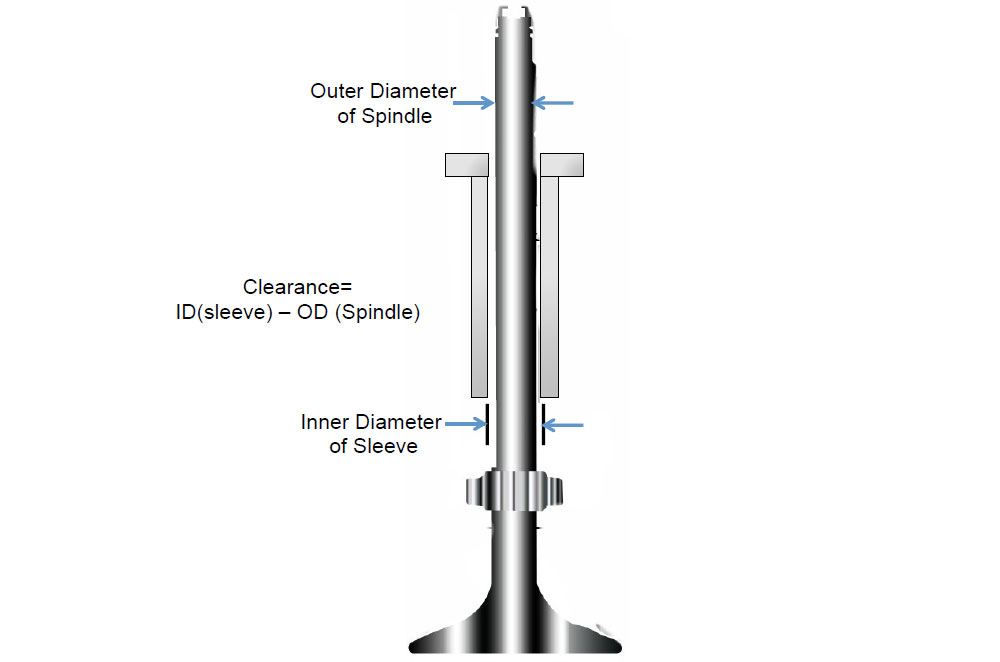

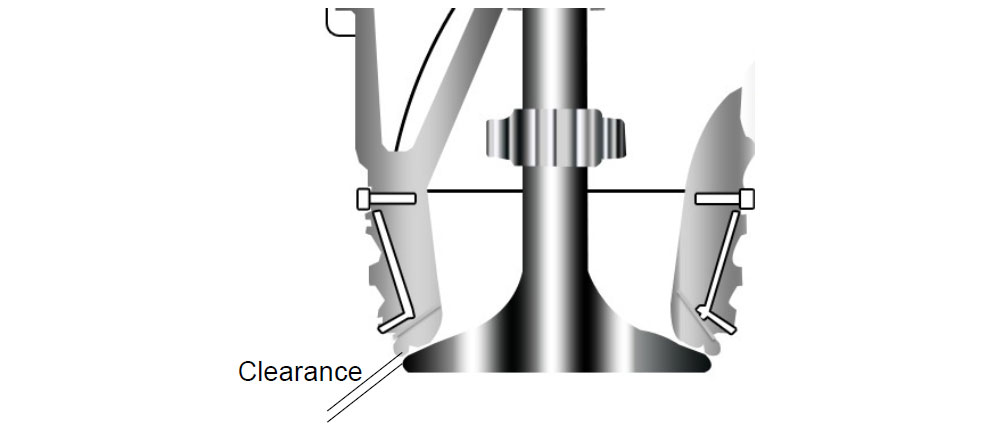

Clearances in Exhaust Valve

With the help of a feeler gauge, check clearance between the valve and the seat. A 1mm feeler gauge should go up to 15 mm deep. This is to ensure that there is clearance between the outer parts of the seating faces of valve housing and spindle.

The clearance between the valve spindle and sleeve is also measured by measuring the difference between the inside diameter of the sleeve and outside diameter of valve spindle. Maximum clearance should be 1mm in the top part and 2 mm in the lower part of the sleeve.