Components of Boiler Water System

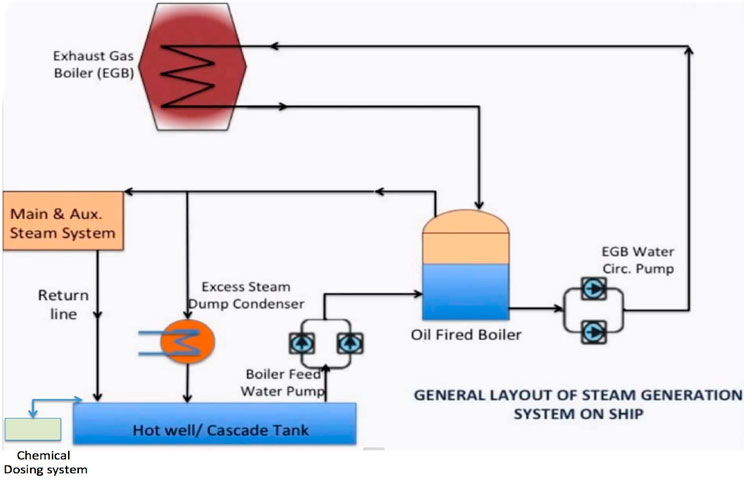

The boiler water system with one auxiliary boiler and an EGB is shown in the below diagram:

The system consists of a boiler feed water tank, also known as cascade tank or hot well, boiler feed water pump, condenser, de-aerator and feed water heater. A chemical dosing unit with a separate chemical dosing pump can be installed to automate the chemical treatment process of the marine boiler.

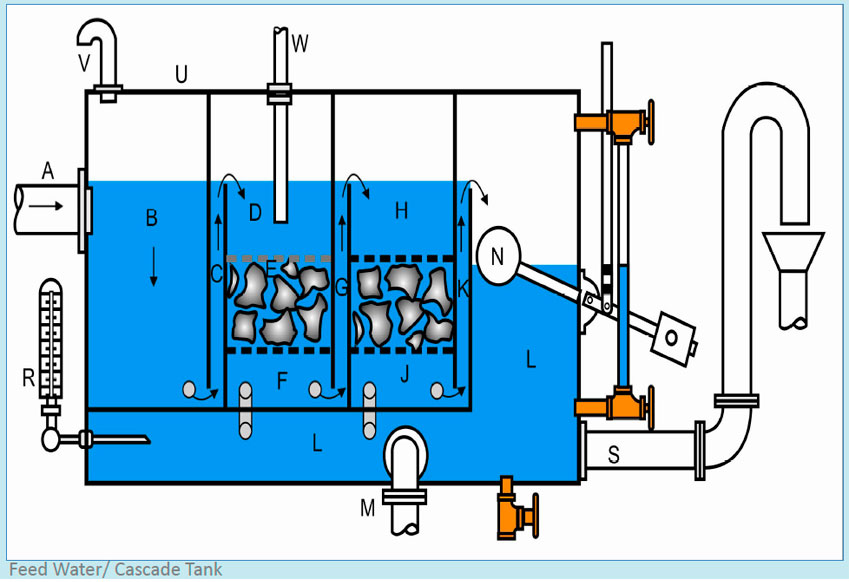

Boiler Feed Water Tank/ Cascade Tank:

Also known as hot well, it supplies hot water feed to the boiler water drum, which is heated to generate steam. The top-up water for the boiler water is supplied to the system via hot well by installing a make-up fresh water (distilled) connection.

A well-designed feed tank is necessary to minimize the oxygen content within the feed system. This is important especially for open type feed system.

The normal construction of a cascade tank should be such that:

- Adequate ventilation is ensured by installing one or more vent pipes whose diameter and number depends on the volume of water

- The entry of the condensate is from a lower point and through a slotted sparge pipe

- The make up water which is at a lower temperature is introduced at the highest point

- The tank has sufficient volume to cope up with transient flows from normal operations without spilling back to feed tanks or overflows

- Tank to have sufficient volume of water at normal working level to allow for 1 hour operation at maximum demand

- Take off to feed pumps to be at least 75mm from tank bottom

- Tank location should be such that it provides head requirement at normal working level for feed pumps

Following equipment/ parts to be installed on a cascade tank for safe operation:

- A salinometer installed for checking the salt content

- A sight glass with bright light at the background to check for oil contamination foaming in the water

- Oil contamination detecting device

- A thermometer to show the current temperature

- A gauge glass to check the level of the cascade tank

- A float switch with alarm at high and low level

- A loaf sponge type filter or oil baffles in the water entrance chamber to absorb small oil leak, which returns to the cascade tank from the oil heating system

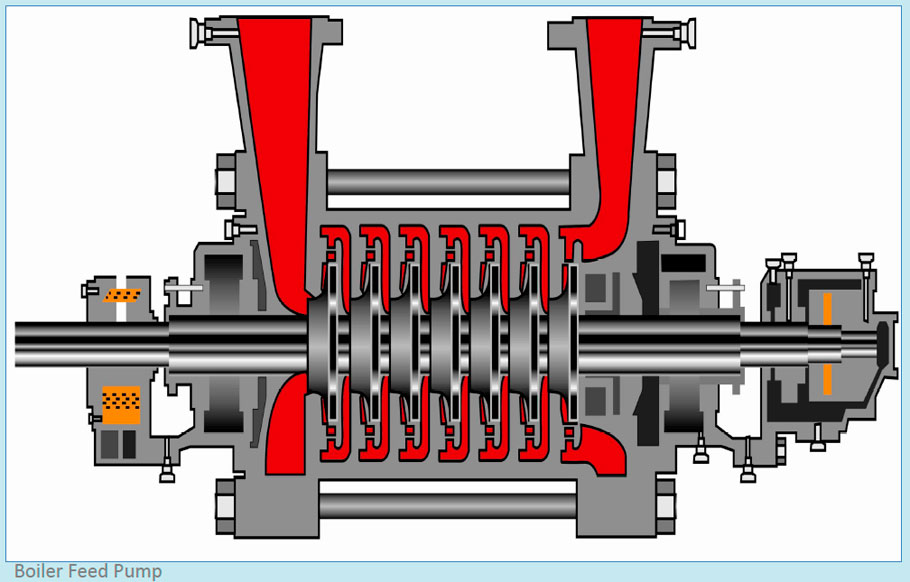

Boiler Water Feed Pump:

Boiler water feed pump is an essential component of the feed circuit. It supplies the required quantity of feed water to the boiler drum by taking suction from the hot well/ cascade tank. The boiler feed water pump is normally a centrifugal pump of multi-stage type. The boiler feed pump capacity must be 1.25 times the steam output of the boiler.

Where boiler water blow down is practiced constantly at volume of about 5% of the allowable steam output, the capacity of the pump must be readjusted and increased to the corresponding percentage value, in this case to 5%.

Normally the feed pumps are equipped with frequency convertor to assist the pump during startup and to create a water pressure, which is above the Pressure inside the boiler.

If not, the pump will be continuously running against a closed valve until it overcomes the pressure. This may lead to damage of shaft seal and water leakage.

For economizer circulating water pump, additional bearing flange is fitted which contains an oversized bearing to absorb axial forces in both the directions, as the inlet pressure is on the higher side. The coupling part of the flange also ensures an optimal alignment between the pump and the motor.

General Troubles in Boiler Feed Pump:

- Seal Leakage: It is the most common problem that is experienced in the marine boiler feed water pump. This can occur because of - damage to the seal resulting from misalignment of the shaft, vibrations, or wrong pump operation

- Bearing damage: The pump comprises of multiple bearings for supporting the revolving shaft. The motor and pump sides have different set of bearings. Any damage or misalignment in the shaft may lead to bearing damage. During start up, if the pump has to overcome high boiler pressure and frequency convertor is not working, the bearing can be damaged

- Cavitation: The cavitation of pump casing occurs due to high temperature of water coming from hot well tank. The higher the temperature, more likely the cavitation is to occur

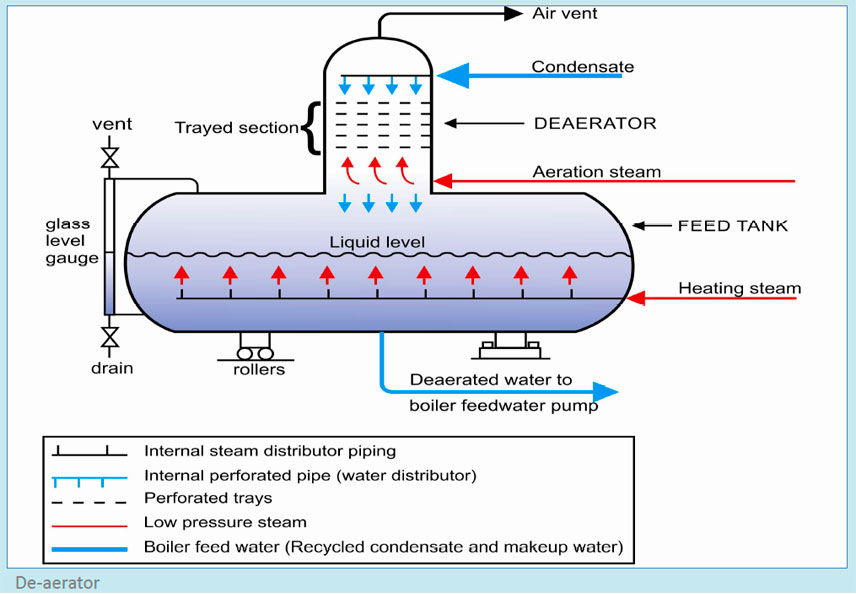

De-aerator:

De-aerator is fitted to remove oxygen and CO2 from the boiler water. This is done to protect the boiler and its tubes from corrosion.

Normally the de-aerator is integrated in the boiler feed water tank or the cascade tank.

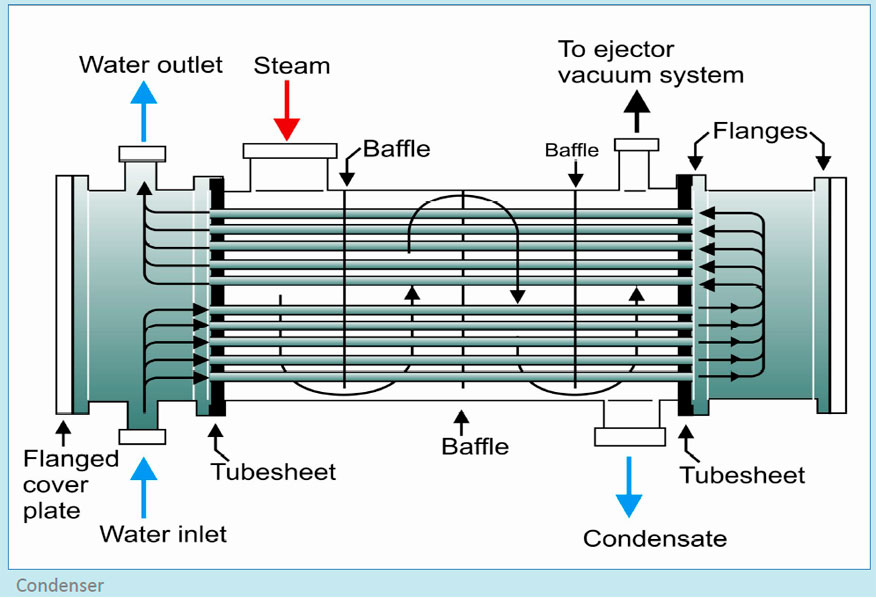

Condenser:

A Condenser is fitted to ensure the steam returning from the ship’s system gets converted into hot water before reaching the cascade tank, from where the feed water pump takes suction.

The condenser is normally seawater cooled but a fresh water-cooled condenser can also be installed depending on the ship cooling water system. The condenser tube leakage is the most common cause for increase in the salt content of the boiler.

It is important to check the condenser tube leakage in the event of high salinity in the marine boiler. If leakage is found, the tube must be plugged using a metal plug or as advised by the manufacturer. The condenser is provided with a steam by pass valve which can be operated to increase or decrease the temperature of boiler feed water in the cascade tank.

Boiler Feed Water

A marine boiler is supplied with fresh water which is know as boiler feed water. Practically the boiler water should be used in its purest form, as it will reduce salt or deposits on the internal surface and tubes of the boiler, giving maximum heat exchanging efficiency for producing good quality steam.

The purity of water supplied to the boiler is very difficult to maintain as the boiler drum receives water from the cascade tank, which is filled from ship’s fresh water tanks and condensate water that returns from the heating coils of various ship’s system.

Generally the main source for the cascade tank is a dedicated fresh water tank (also known as boiler feed tank or distilled water tank), which is filled from fresh water generator. This is the best source of boiler water as it contains minimum impurities. In some ships, the cascade tank is supplied with water from fresh water tank taken from shore.

The shore water often contains several impurities including salts. It is taken to compensate the quantity of water when the production of FWG is less than the required.

The produced steam usually contains liquid droplets and gases. The water at the bottom of the boiler also comprises of foreign deposits and salts. During the heating process, these impurities can get carried with steam to the engine room systems.

It is therefore always recommended to use water from the distillate sources such as fresh water generator of the ship. The distillate water will also contain minor parts of various salt combinations, which must be removed by chemical treatment of water. The distillate may contain dissolved gases like oxygen and CO2, which may cause corrosion inside the boiler, condensate system and piping system.

Problems in Boiler Feed Water System

The main problems that occur in the boiler feed water system which can lead to reduction in the boiler efficiency, increase in the operating cost and in some cases equipment failures are:

1. Scaling: Scaling occurs on the heat transfer surface of the boiler due to the formation of interlocked crystalline layer of minerals. Severe scaling will occur once the mechanism exceeds the solubility limit of the mineral substances resulted from elevated temperature and solid concentration at tube and water surfaces.

The scale is generally of carbonate/ sulphate complex of calcium and magnesium along with calcium carbonate and magnesium sulphate. If this condition continues to grow and remain unchecked, it will cause reduction in the boiler efficiency due to ineffective heat exchanging process. Extreme condition will lead to overheating and rupture of boiler tubes.

2. Sludge formation: Sludge is a form of agglomerated suspended material which generally floats with water in the early stages. Once the boiler water is unable to keep the sludge in suspension, it will settle on boiler and tube surfaces. The sludge that settles over the heat transfer surface of the boiler is known as baked-on-sludge, which also acts as heat insulator and leads to crevice corrosion.

There is no fixed composition of sludge as any type of impurities floating in the boiler water may form sludge in later stages. For e.g. oil, loose corrosion products, insoluble mineral precipitates etc.

3. Corrosion: Due to the nature of boiler operation and impurities in the boiler water, it is almost impossible to eliminate the corrosion factors completely. There are mainly 4 types of corrosion with respect to the boiler water that can damage the boiler if left unattended or preventive measures are not taken:

- Mineral Acid Corrosion- This type of corrosion mostly affects the complete boiler especially low-pressure boilers, which are widely used in ships. The main reason being the ingress of seawater either from condenser leakage or distiller carryover, resulting in mineral acid corrosion. If this condition is extended without treatment, it will rapidly corrode the metal in contact

- Carbonic acid corrosion: This type of corrosion is the result of steel piping being chemically dissolved due to carbon dioxide reacting with water to form carbonic acid in the steam system. This may lead to deposits in the steam traps, condenser and other in line systems where condensate can be collected. The deposit, which are normally in reddish brown powder form, can be confirmed by putting in a piece of paper and bringing it close to a magnet. If the powder is magnetic in nature, it is due to carbonic acid corrosion

- Crevice corrosion: Also known as differential concentration process, it is among the most severe types of corrosion in the boiler where an ionic species is present in significantly different concentrations over the metal surface at its adjacent areas. This difference causes depletion of the species within the crevice, setting up an electrochemical corrosion cell which results in rapid pitting attack.

The most common type of crevice corrosion is known as differential aeration where oxygen is involved with chloride or sulphate ion. The environment required for such corrosion is developed by the corrosion deposits, which are already present within the boiler heat transfer surface - Oxygen metal depletion: This type of corrosion is due to excess oxygen in water. It is also one of the severe forms of corrosions in the boiler. While basic corrosion in boilers may be primarily due to reaction of the metal with oxygen, other factors such as stresses, acid conditions, and specific chemical corrodents may also have an influence and produce different forms of attack

The first preventative measure against such corrosion is to remove as much oxygen as possible from the cascade tank by increasing its temperature (as near to 90°C as possible) and by providing the maximum possible venting for the tank.

An oxygen-scavenging chemical fed to the feed water reduces the remaining dissolved oxygen. The aim is to decrease the amount of oxygen to a level where it provides an insufficient driving force to perform depolarization

How to Tackle Boiler Feed Water Problems?

1. Scale formation: The best way to prevent scaling of boiler internal surface and fittings is to provide good quality of demineralized feed water to the boiler. The purer the feed water, the weaker is the driving mechanism to form scales.

The post scaling treatment involves using boiler chemicals also known as chemical scale inhibitors, which will detach the hardness caused by cat-ions, magnesium and calcium from the scale forming minerals and replace them with sodium ions.

2. Sludge formation: Again the best preventive method to minimize the sludge formation is to provide a clean and impurity-free feed water to the boiler. A regular scum blow down will also remove the floating impurities that may later take the shape of hard sludge deposits.

Controlled rate of bottom blow down on daily basis will also reduce the possibility of sludge and sediment deposits in the boiler surface. Chemical treatment will also help in keeping the sludge in floating state.

3. Corrosion: Mineral acid corrosion- The preventative treatment for this corrosion is to feed alkaline chemicals to neutralize the acids and maintain a buffer reserve of alkalinity.

P-alkalinity of 100-150 ppm or pH in the range of 10.8 to 11 must be maintained to ensure that the boiler metal is least susceptible to this type of corrosion.

4. Carbonic acid corrosion: Feeding and recycling a neutralizing amine is a good option. Add chemicals, which controls the condensate to the circuit at a point where circulation is high.

Boiler Water Chemical Dosing Unit

Boiler water treatment is the best available procedure to compensate and treat any impurities in the boiler water and reduce chances of corrosion and other major problems.

The chemicals, which are added to the boiler water can be included in the system either manually or by using a chemical dosing unit.

Chemical Dosing Unit:

A separate chemical dosing unit can be installed for better treatment of boiler water. The unit comprises of a chemical dosing tank and a chemical dosing feed pump. The chemical dosing pump is a type of metering pump, which controls the dosing of liquid chemical in to the pressurized pipe of the boiler water system. A small chemical feed tank is provided where the chemical is mixed with water as per the prescribed ratio. From this tank, the pump takes the suction and supplies the chemical to the boiler water.

A feed control knob is provided in the pump, which determines the rate of chemical to be supplied to the boiler water system. The chemical dosing pump, unlike any other system, requires proper maintenance and careful operation for safety and reliability. The normal maintenance interval can be three months but it may vary depending on the usage of the system.

Following points to be considered while carrying out maintenance on the chemical feed system:

- Start and run the pump for short duration to check the correct feed rate before putting the pump into operation

- Check all the pipe connections are firmly tightened

- Check the seepage of the chemical from the vent

- Check the functioning of discharge and suction valve (tightening and leakage)

- Check the diaphragm for any damage and ensure the bleed function is working correctly

- Ensure all electrical connections of the pump are tightened and there is no visible wear

Boiler Feed Water Requirements and Treatment

The boiler water comprises of several chemical impurities, which must be treated to ensure they do not damage the internal surface of the boiler.

Following are some test values and properties which are to be maintained in the boiler water to ensure boiler internal parts are not hit by corrosion or other related problems.

Appearance: The appearance of boiler feed water is a good indication to assess its condition. It is necessary that the feed water is clear and free from mud in both boiler and cascade tank. If the appearance of feed water is muddy or unclear, the hot well tank and boiler must be cleaned. If foaming of water occurs, it is to be removed by scum blow down.

Oil content: There should be no oil content of any kind inside the boiler or cascade tank at any time. If any traces of oil are found in the boiler gauge, immediate action must be taken to cut off the source of oil leakage followed by scum blow down. Chemicals having coagulant effect on the oil must be added for ease of filtration and removal.

Chloride content: Chloride content determines the level of chloride salt in the boiler water, which may be due to ingress of seawater or impure water (shore water). Chloride ions, unlike other ions that enter the boiler, are extremely soluble and do not precipitate or decompose when subjected to boiler conditions.

The required level of chloride in the feed water should be less than 15 ppm. The required level of chloride in the boiler should be in the range of 50- 120ppm depending upon the boiler pressure and manufacturer recommendation.

Conductivity: Conductivity is a measure of the ability of water to conduct electric current. The ability to conduct electricity is related to the amount of dissolved (ionizable) solids in the water. The value of conductivity should be less than 2000 μS/cm at 25 °C .

Phosphate: Phosphates are used in boiler water to precipitate calcium hardness in a form, which can be readily removed by blow-down. This can be achieved only when the phosphate levels along with the alkalinity/pH levels are in correct numbers. To a small extent, phosphate also helps prevent boiler corrosion by forming a protective iron phosphate coating on the boiler metal. The required level of phosphate in the boiler water is 20 -50 PPM.

Alkalinity: Within the initial stages of feed water, alkalinity is commonly the result of bicarbonate and carbonate ions. In treated waters, alkalinity may also be contributed by hydroxide, phosphate, silicate, and other treatment ions. The required value of P-alkalinity in the boiler water is 100-150 PPM.

Hardness: The primary composition, which results in hardness of water, is mainly because of dissolved calcium and magnesium compounds. Hardness is the main source of scaling in the heat transfer surface of the boiler. The required value of hardness in the feed water is 0 – 5 PPM.

Hydrazine: Hydrazine is usually added in the boiler feed water for the purpose of maintaining residuals to prevent corrosion by dissolved oxygen. The required value of hydrazine in the boiler water is between 0.1 - 0.2 PPM.

Use of chemicals and their quantity depends on the boiler water test values and chemical suppliers recommendations. Ships are provided with boiler water testing kits to check the above stated values.

Maintenance of Boiler Feed Water system

The maintenance of boiler feed water not only depends on the chemical treatment but also on the daily and planned maintenance of condensate, feed system and boiler. It is very important to ensure that the feed water is maintained at a temperature of 85 – 95 °C for deoxygenizing. The crew involved in the maintenance of the boiler should be skilled in operation and up-keeping of the complete boiler system.

Mentioned below are some recommended water maintenance schedules to be followed for up-keeping of the system:

Daily:

- Gauge glass blow-down

- Test and analysis of feed and boiler water

- Checks on the feed water pump pressure, temperature and current

- Check for any leakages in the system

Weekly:

- Scum blow down

- Bottom blow down in low load condition for short duration (the frequency may vary depending upon the chloride content in the water)

Monthly:

- Check the functioning of salinometer

- Check the functioning of oil detection system

Six monthly:

- Inspection of condenser for leakage

- Inspection of chemical dosing unit

Yearly:

- Cleaning of hot-well and deaerator for corrosion and scaling

- Waterside inspection and cleaning

References

A Guide to Boiler Operation and Maintenance. Anish Wankhede [2015]