Piston is the only moving component in the combustion chamber and is responsible for converting the generated gas forces into mechanical reciprocating motion, which finally drives the propeller.

Design and Material

A two-stroke piston comprises of

- piston crown- which forms the top most part, exposed to the combustion chamber

- piston skirt- which acts as a guide inside the liner and also opens and closes the air intake or scavenge ports in the liner for combustion air entry

- piston rod - which connects the piston to the crosshead

Piston Crown is normally casted from chrome nickel molybdenum alloy steel as it is exposed to high temperature and thermal stresses.

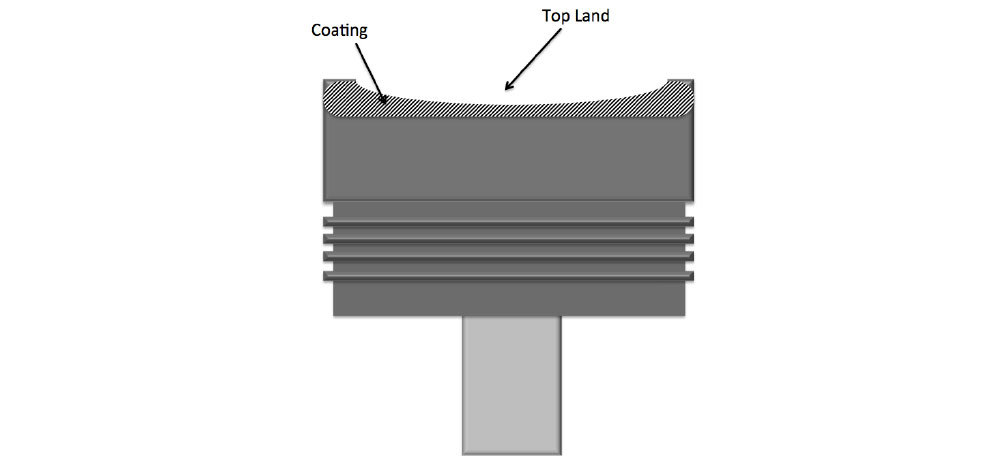

The top land of the piston is designed in convex or concave shape as it makes a hemispherical combustion chamber in conjunction with the cylinder head, resulting in higher efficiency.

The top land is sometimes coated with temperature resistant material to protect the crown from overheating. Piston Rod is made up of forged steel.

Nowadays, Sulzer and MAN engine pistons have chromium-coated grooves for long operating life. Both these engine pistons are equipped with two or more bronze band rings integrated in the skirt part, for assisting the piston in running-in phase.

Cooling Method:

The main engine piston is cooled by one of the two cooling mediums- oil or water.

Water-cooled pistons were mainly used in old MAN engines and Sulzer RND engines.

Nowadays both MAN and Sulzer engines prefer oil cooling to conventional watercooling piston as the former reduces the risk of lube oil contamination in case of leakage.

In MAN engine: The cooling oil comes from main bearing to the crosshead pin and then reaches the crown through the bores provided in the piston rod. A return line bore is also provided in the rod, which connects to crosshead pin sides and the oil goes to the sump.

In SULZER engine: The cooling oil comes to the piston from an articulated or swinging arm supplying lube oil at system pressure. A separate manifold runs throughout the engine, from which oil is supplied to the articulated arm of each unit.

Types of 2 Stroke Piston

Every engine maker, especially the big players such as MAN and Sulzer are introducing new piston designs to improve the overall efficiency of the combustion space and to increase the working life of the piston.

SULZER Piston:

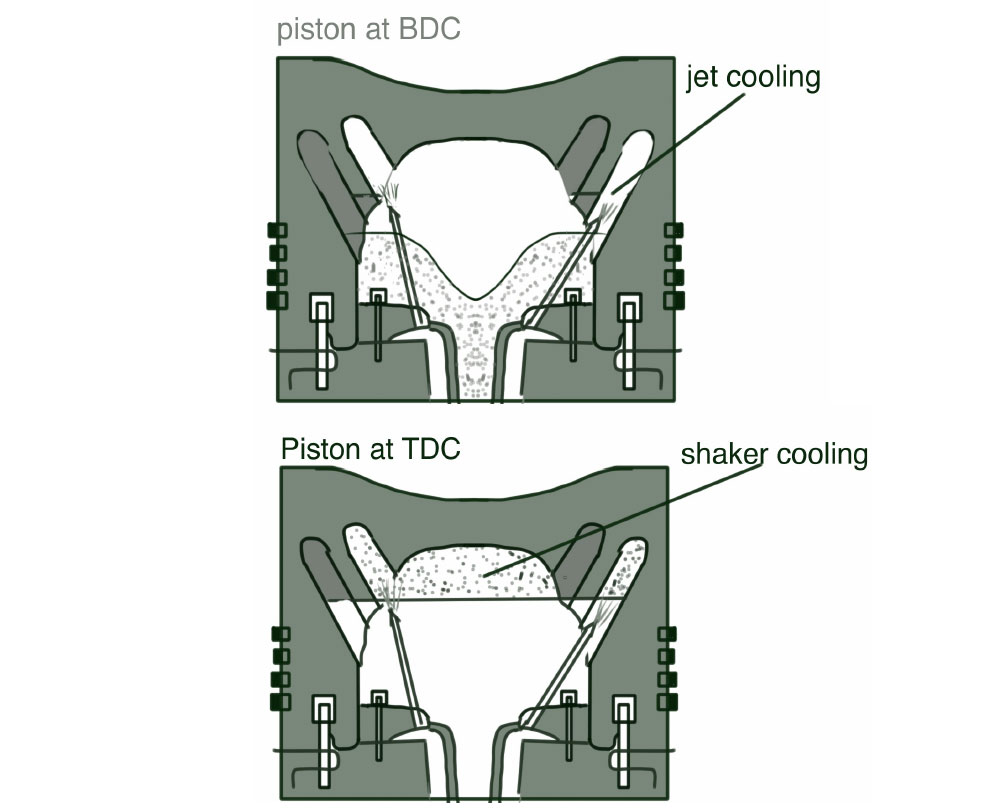

The new SULZER piston with concave crown comes with Jet-Shaker cooling design, wherein the jet nozzles are attached to the cooling passage of piston rod.

The piston crown design which comprises of bores and nozzles ( for supplying cooling oil with high pressure), provides better uniform cooling and reduces crown thickness and overall piston weight. This is known as jet shaker method as during downward movement of piston, the nozzle sprays the oil jet inside the bore and when the piston moves upward, the oil inside the piston crown shakes for efficient cooling.

MAN B&W Piston:

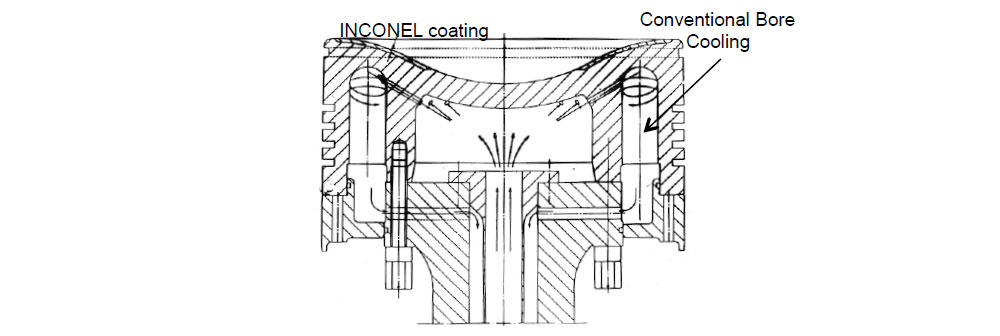

The new MAN engine uses simple bore cooling piston and jet nozzels, which comprises of oil passage within the piston crown for uniform cooling. The MAN engine also uses a top layer thermal coating over the crown, known as INCONEL 625 coat, which is 8mm thick and protects the crown surface from overheating.

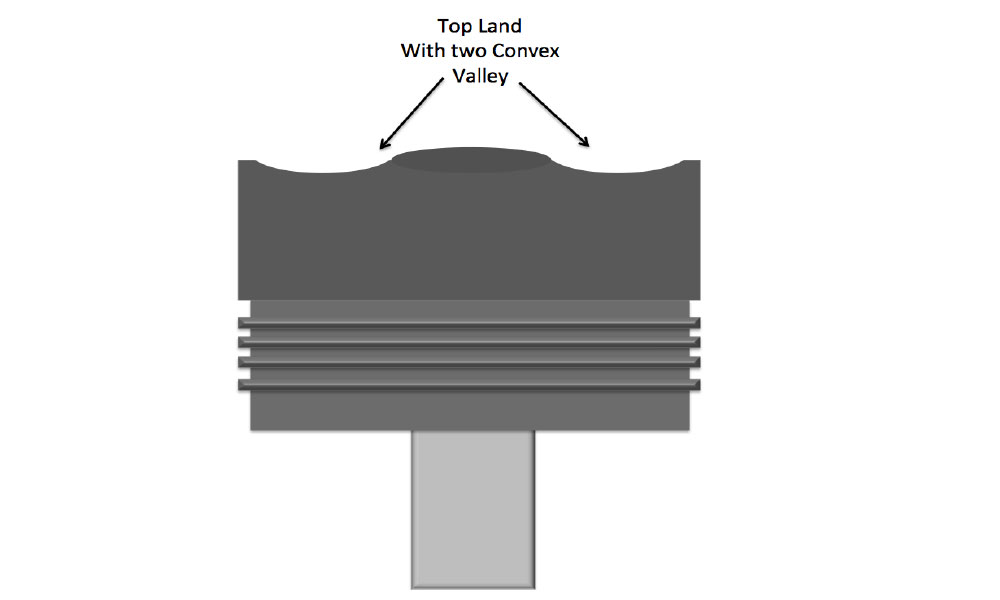

The latest development in MAN engine pistons is OROS Piston, which has top land with double convex valleys.

The main advantage of this type of piston over the conventional designed piston is :

- Reduction in the thermal load and temperature of piston crown

- Increase in the overall working life of the piston

- Formation of better combustion chamber, leading to efficient combustion

The max temperature reached in gas side of a piston during combustion process in conventional shape piston is 510 deg C but it reduces to 420 deg.C in OROS type piston.

Common Problems in Piston

The most common problems experienced in a marine engine piston are:

- Cracks on the surface

- Deformation of piston crown top

- Burning off of piston crown top

- High temperature of piston while running

- Scuffing of piston

- Worn-out piston ring grooves

Main reasons for problems:

- Inadequate circulation of coolant

- Excessive deposits inside the cooling space

- No or poor water treatment

- Poor cylinder lubrication

- Faulty piston ring

- Liner distortion

- Piston wrongly aligned

- Overloading during combustion

- Excessive water in fuel

- Insufficient air

- Late fuel injection

- Faulty fuel injector leading to more penetration of fuel

- Wrong running-in after major overhaul

- Scavenge fire

- Thermal stresses due to cold starting or low temperature of scavenge air

Inspection of Piston

Check the following while doing piston inspection:

- Carbonaceous deposits on the crown and sides

- Crown top surface-for burning and cracking damage

- Top ring groove & side wall - for crack / deformation and wear

- Other ring grooves - for distortion / wear

- Cooling passage - for scaling / chocking

- Skirt - for wear / rubbing marks

- Wear ring / rubbing ring for scuffing

Measurement and Test

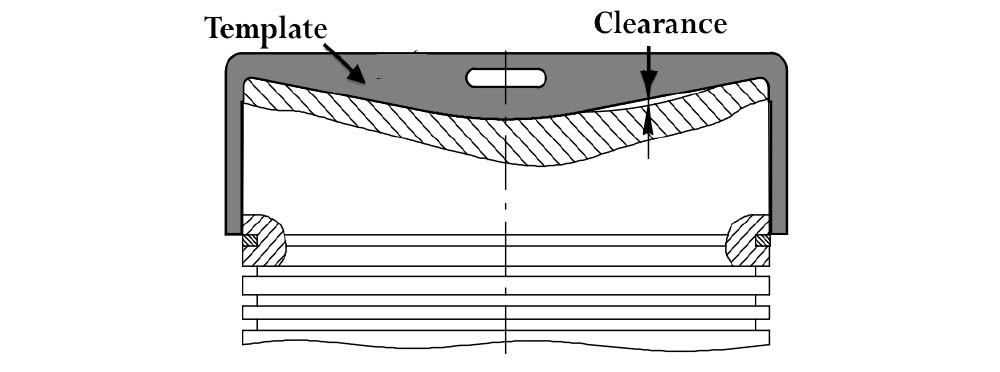

Measurement of piston top land: The piston top land is prone to burn-outs due to direct contact with high temperature combustion and malfunctioning of the injectors, resulting in longer penetration of fuel which deforms the piston top.

The piston top land wear down is measured with the help of a template which is fitted on top of the piston crown and the clearance between the template and top land is measured with the help of feeler gauge.

| Max. Permissible burn-away |

| MAN MC-C - Standard piston top: 20mm - Inconel piston top: 8mm |

|

SULZER RTflex 96C - Standard piston top:10mm |

Pressure Test of Piston:

It is important to pressure test the piston, which has been taken out from the unit and cleaned for reuse. Following Procedure is to be followed:

- Invert the piston so that the base of the piston palm is facing up

- Fill the piston with water and keep an air hose ready

- Fit the pressure testing tool at the palm of the piston and ensure no water leaks from the connection

- Connect the air hose to testing tool and supply air pressure up to 7 bar

- Shut the air and isolate the piston in this condition

- Check for any leakages from all contact surfaces and sealing rings

- Check crown for any crack or water

- Keep the piston pressure charged for 2-3 hours and check that the pressure is stagnant which indicates no leakage

Difference Between SULZER and MAN Piston

| SULZER | MAN |

| Crosshead bearing surface area is smaller | Large crosshead bearing surface area |

| Bearing shell is of smooth surface | Bearing shell has grooves with machined channel to retain lubricating oil |

| The lube oil is supplied by separate crosshead pump | The lube oil is supplied by main lube oil system pump |

| The lube oil pressure is maintained at 12-16 bar | The oil pressure is maintained at 2-4 bar i.e. system pressure |

| Lube oil is injected once per cycle @ 20 deg. Before TDC | Lube oil is injected twice every engine cycle |

| Lube oil is supplied to crosshead by means of swinging or articulated pipe attached to the crosshead | Lube oil is supplied to the crosshead by means of telescopic pipe connected to the guide |