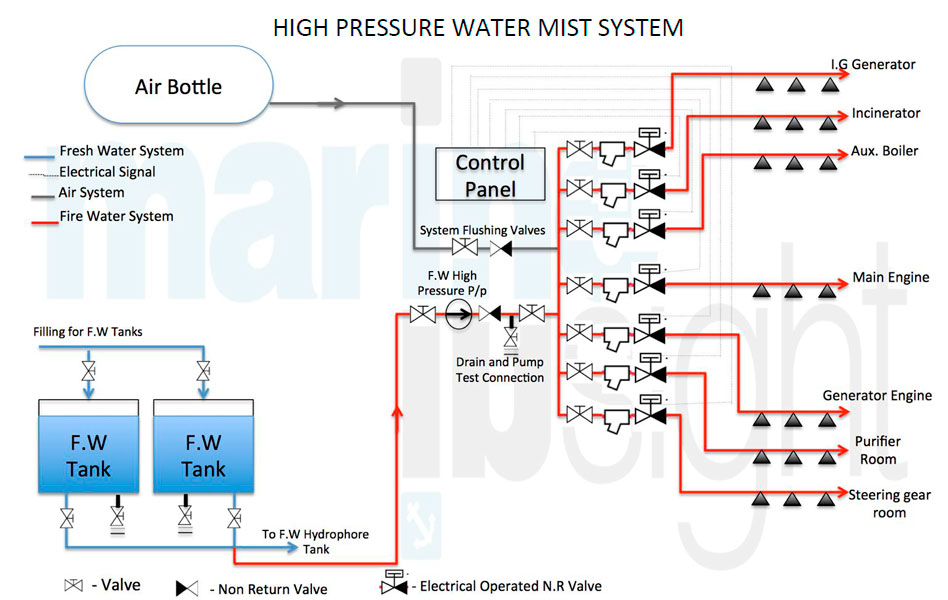

The high-pressure water mist/fog system provides water mist protection to certain areas and machinery spaces in the engine room. It is independent of any other fixed fire fighting system, such as foam or C02 systems.

Fine droplets of water tend to exclude oxygen from the atmosphere in the vicinity of fire, thereby starving the fire. When these fine droplets come in contact with hot burning material they immediately evaporate due to large surface, producing a faster cooling effect. Also, as the water droplets convert into steam, it further helps in smothering the fire.

High-pressure water is injected through a special nozzle, which breaks the water droplets into fine mist.

The distance between any two nozzles is very critical as area covered by one nozzle must be such that no space is left unsprayed in the fire location.

Following are the most common areas covered by water mist system:

- Incinerator room

- Auxiliary boiler room

- Auxiliary generators

- Main engine cylinder head platform

- Purifier room

- Inert gas generator room

- Steering gear room

A fresh water pump takes suction from fresh water tank to supply high-pressure water to the sprinkler system. Each area is isolated by valves, which can be opened during fire. The system is kept at constant stage of readiness.

"During engine room painting, ensure these spray nozzles are not clogged with paint as it may impair their operations"

Procedure for Operation:

- Check the level of fresh water tank

- Ensure the power is available for the system including fresh water pump

- Ensure all valves in the system are in open condition

- Check drain valves in the system are shut

- Check air blow valve is closed

- Check test valves is shut

"When hot work is carried out in the engine room, ensure to switch OFF the sensors of that area else it may lead to activation of sprinkler system."

Procedure for testing the system:

- Switch the system to manual operation

- Close the individual outlet valve located after the section valves to all protected spaces (1 for generator room, 2 for incinerator and so on)

- Open the test valve normally located below outlet valves & open the line drain valve

- Open the drain valve in the line

- Open the section valve manually for one section and check if the pump starts

- Shut the section test valve and carry out the same procedure for other sections

- For auto functioning section valves, push the section valve button in the panel

- Check if the pump starts and section valve is in open position and the mist release lamp is ON. Reset the system and repeat the test for other sections

References

A Pocket Guide To Fixed Fire Fighting Systems and Emergency Procedures For Ship’s Engine Room (Author: Marine Insight)