The engine camshaft is used to drive the fuel pump and to operate the exhaust valve mechanism. It is located in the housing for the roller guides. The camshaft bearings consist of two mutually interchangeable bearing shells, which are mounted in hydraulically tightened casings.

A number of segments are joined together to form a complete camshaft unit for the engine. These segments are connected to each other by SKF sleeve coupling.

In SULZER engine, the reversing of the engine is done by changing the direction of rotation of the camshaft. For this, a separate hydraulic reversing servomotor is fitted within the pump housing in every segment of the crankshaft, to assist in engine reversing.

In MAN engine, the camshaft rotates only in one direction and does not integrate any hydraulic means for reversing the camshaft.

The Camshaft is driven by crankshaft either by chain drive or by gear drive.

MAN engine uses chain drive and SULZER uses gear drive.

These driving mechanisms (gear or chain drive) are located either at the end or at the center of the engine, depending upon the number of units. System oil is used as lube oil in the camshaft for lubricating the bearings.

Cam Profiles and Types:

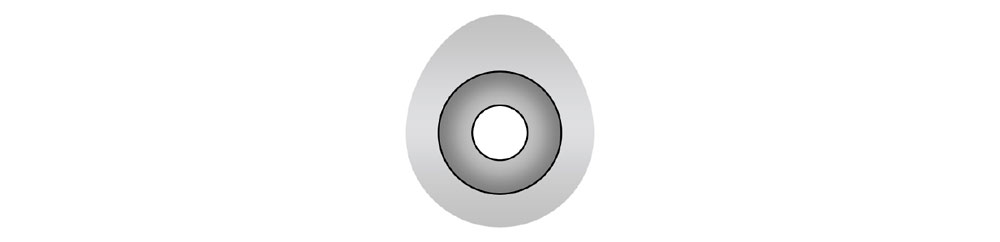

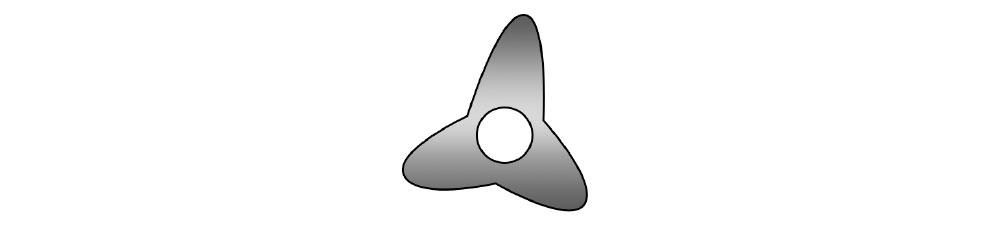

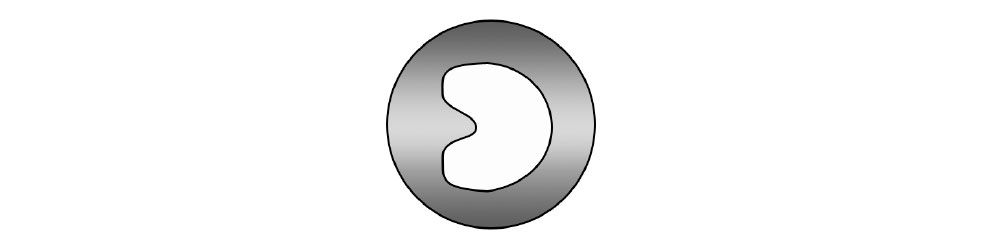

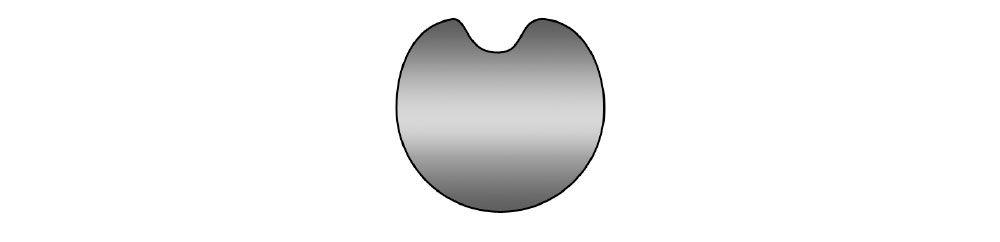

The most important part of the camshaft is the CAM, which controls or operates the exhaust valve and the fuel pump. The cam consists of two parts, a profile and a base circle.

The curvature shaped cam profile drives the follower and regulates the injection time of the oil. Base circle, which acts as the base, is the smallest circle of the cam profile. When the follower is over the base circle, no operation of exhaust valve or fuel pump takes place.

Following are the different types of CAMs used in Marine engines:

- Single lobe cam

- External cam

- Regular Cam

- Multi lobe Cam

- Internal Cam

- Inverse Cam

Material:

The Cams are made from heat-treated hardened steel. The camshaft bearings are shell type bearings, which are white metal lined bearings.

Inspection:

- Check the condition of cam surface for scoring marks. As the inspection must include the entire surface of the cam, the cam should be turned the whole way round during the inspection

- Check the condition of camshaft bearing clearance

- Check correctness of cam timing with the help of pin gauge

Checking Camshaft Timing (MAN engine):

- Ensure that the main lube oil pump is isolated well in advance

- Bring the No.1 unit to Top Dead Centre (TDC). Ensure this position by checking the flywheel marking

- There are markings provided in the camshaft housing and at the center of each cam.

- With the help of pin gauge, check the deviation from the marking. If the values are outside maximum permissible lead angle corresponding to the housing markings, adjusting of camshaft is required

- Clear the cams by lifting the exhaust valve and fuel cam roller

- Remove the shield covering the coupling flange from the camshaft, which is nearest to the chain drive

- Remove the oil tray from the bottom

- Dismount the plug in the coupling flange and mount a ‘three snap-on connector”

- Connect a hydraulic jack and pump to the connectors

- Apply light oil pressure to vent the system. Once venting is done, tight the coupling

- A special spanner is provided to rotate the cam, mount the same

- Apply high pressure oil until oil seeps shaft, below the coupling flange

- Rotate the camshaft by means of a tool till the mark matches both the sides of the pin gauge